Barcode & RFID solutions for returnable asset tracking

Returnable asset tracking for industrial pooled asset fleets. Serialise every asset, see where it is, who has it and what it contains, then automate your processes, and charging models around it.

Returnable transit packaging delivers sustainability and lower cost, but only if assets keep moving. Our hybrid barcode and RFID solutions give you live visibility of location, custody, condition and contents across plants, partners and customers. Reduce loss, increase turns and simplify billing, with standards-based data that plugs straight into your ERP or WMS.

Key challenges in returnable asset tracking ...

Shrinkage and misplaced assets

Reusable items leak from the pool when visibility is weak. Serialised IDs and automated reads at control points show exactly where assets are and who last handled them.

Low utilisation and slow turns

Idle assets create stockouts and inflated pool sizes. Movement events, dwell time alerts and route insights help you balance the fleet and increase turns.

Per-use billing friction

Per-use charging only works with auditable custody. Our system maintains a complete history of movements and contents so invoices can be created with confidence.

Hygiene, wash and repair control

Automated rules trigger washing, sanitising or inspection based on time, use count or detected damage. That keeps assets serviceable and compliant.

Multi-partner complexity

Barcode and RFID reads from suppliers, carriers, depots and customers are standardised and streamed into your systems, so the wider ecosystem remains simple to manage.

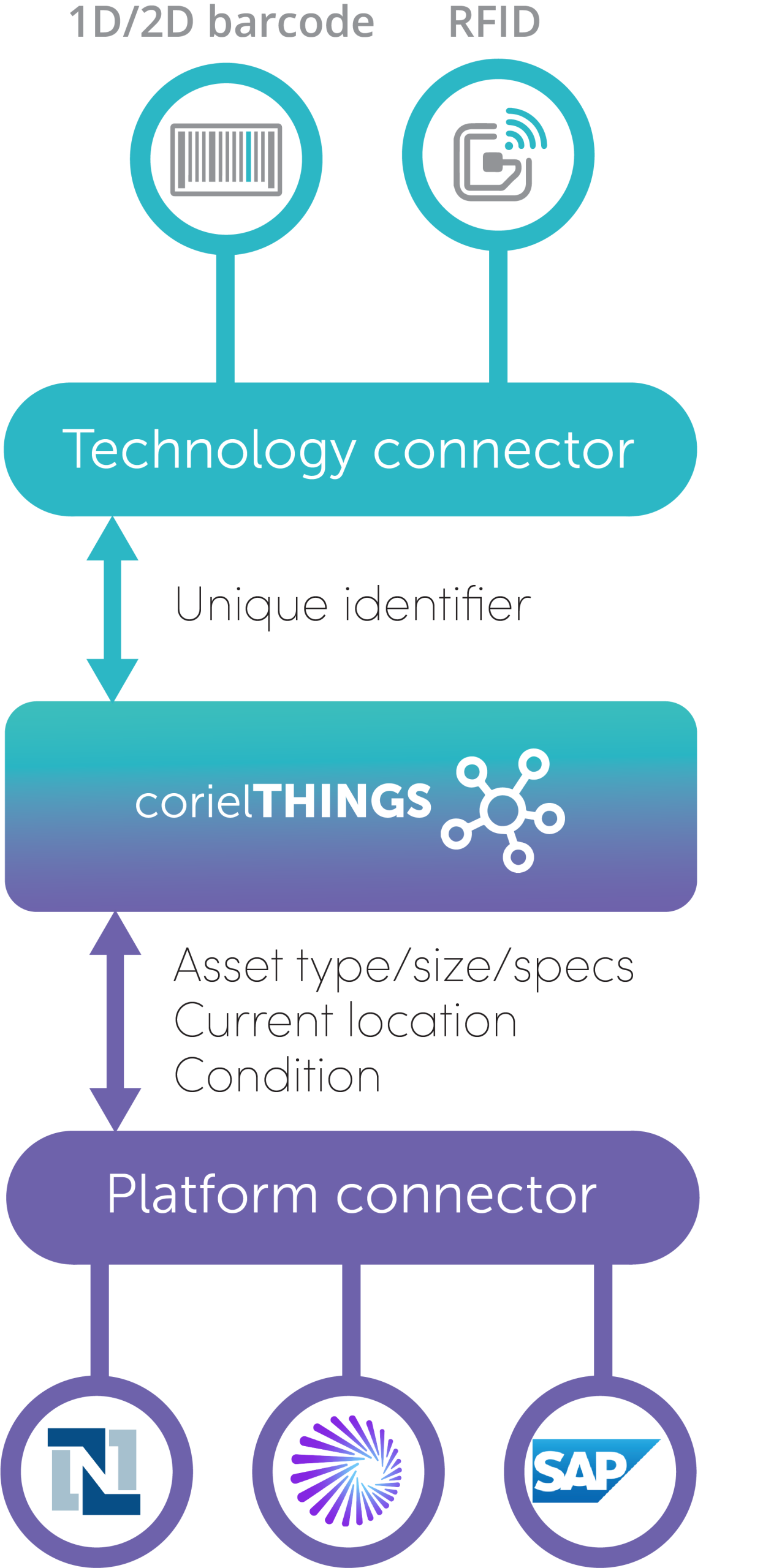

Make all your assets intelligent ...

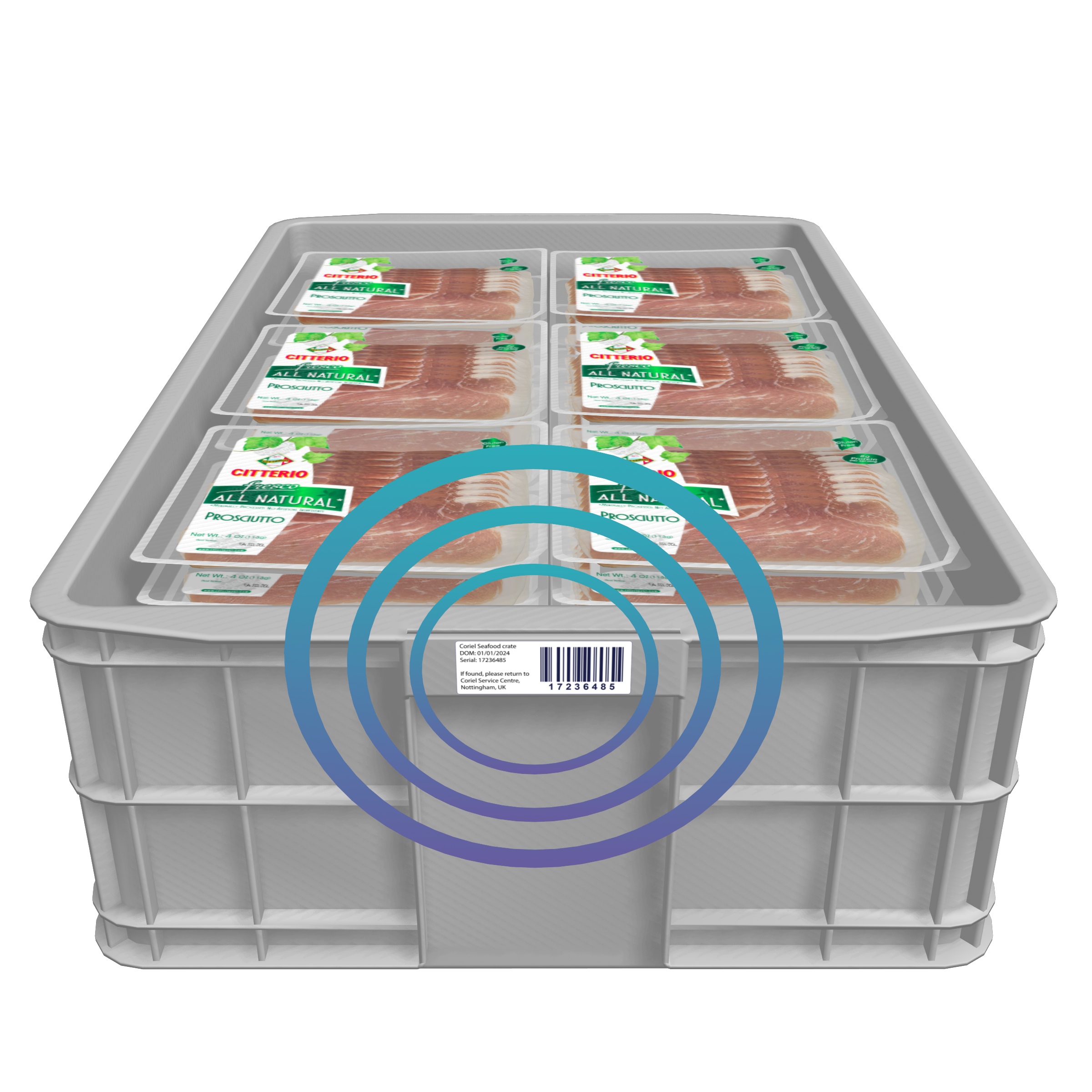

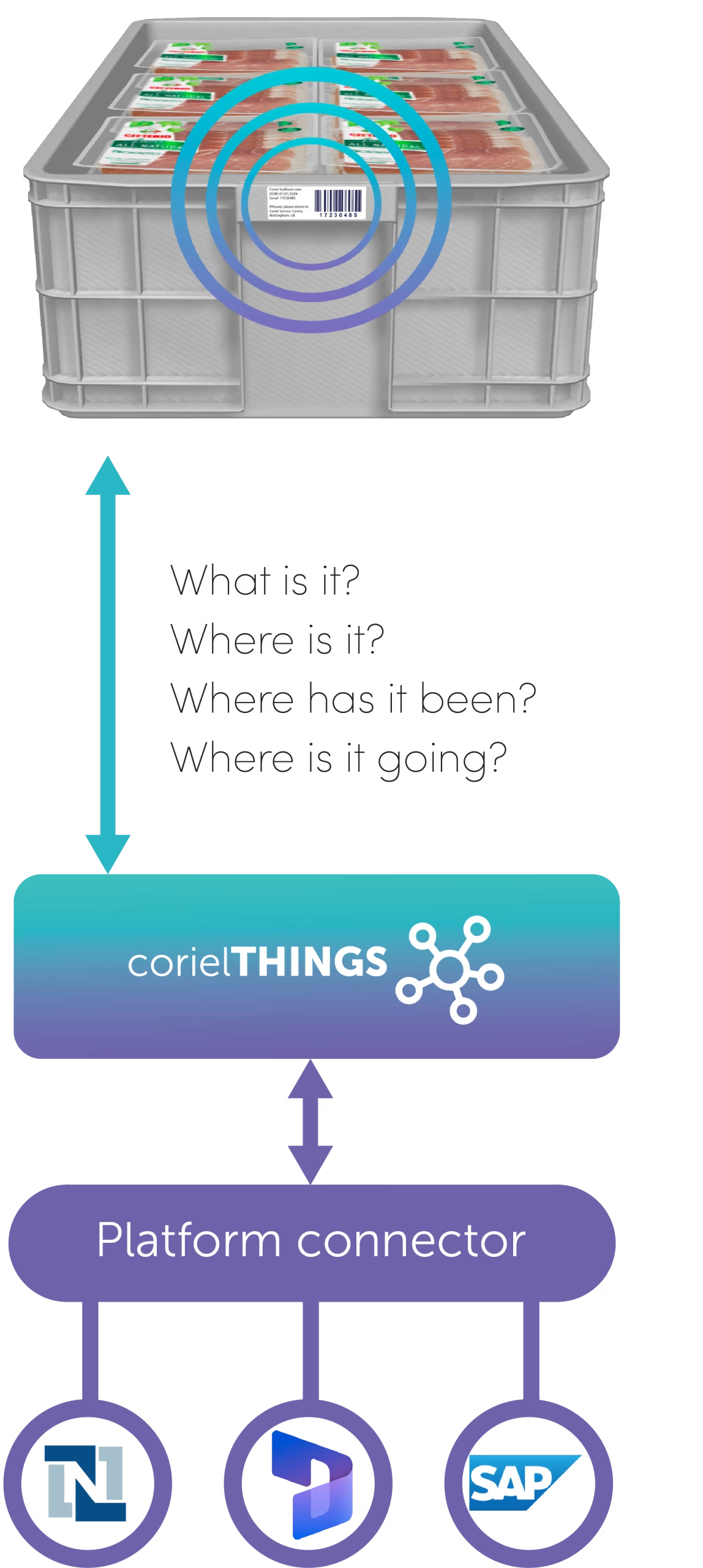

Using GS1 and EPC-based identifiers, corielTHINGS programs durable barcodes, QR codes and UHF RFID tags for every item. A unique digital link connects the physical asset to its cloud record. From that point you can:

- Track precise micro and macro location across the supply chain

- Associate load contents for item-level traceability

- Record condition, maintenance and wash cycles

- Monitor partner usage and custody

- Optimise pool size and distribution to match demand

What assets can you track?

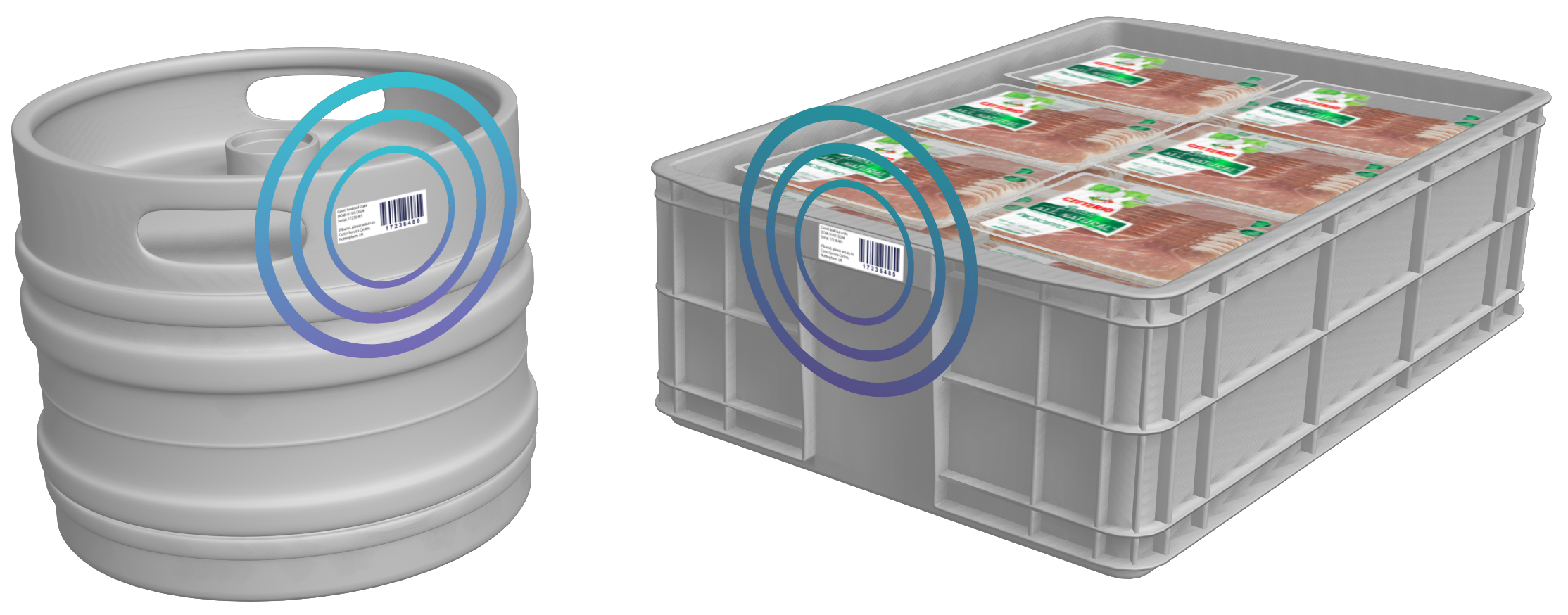

Totes, trays & crates

Pallets, stillages and roll cages

Kegs, casks and containers

IBCs and drums

Gas canisters and cylinders

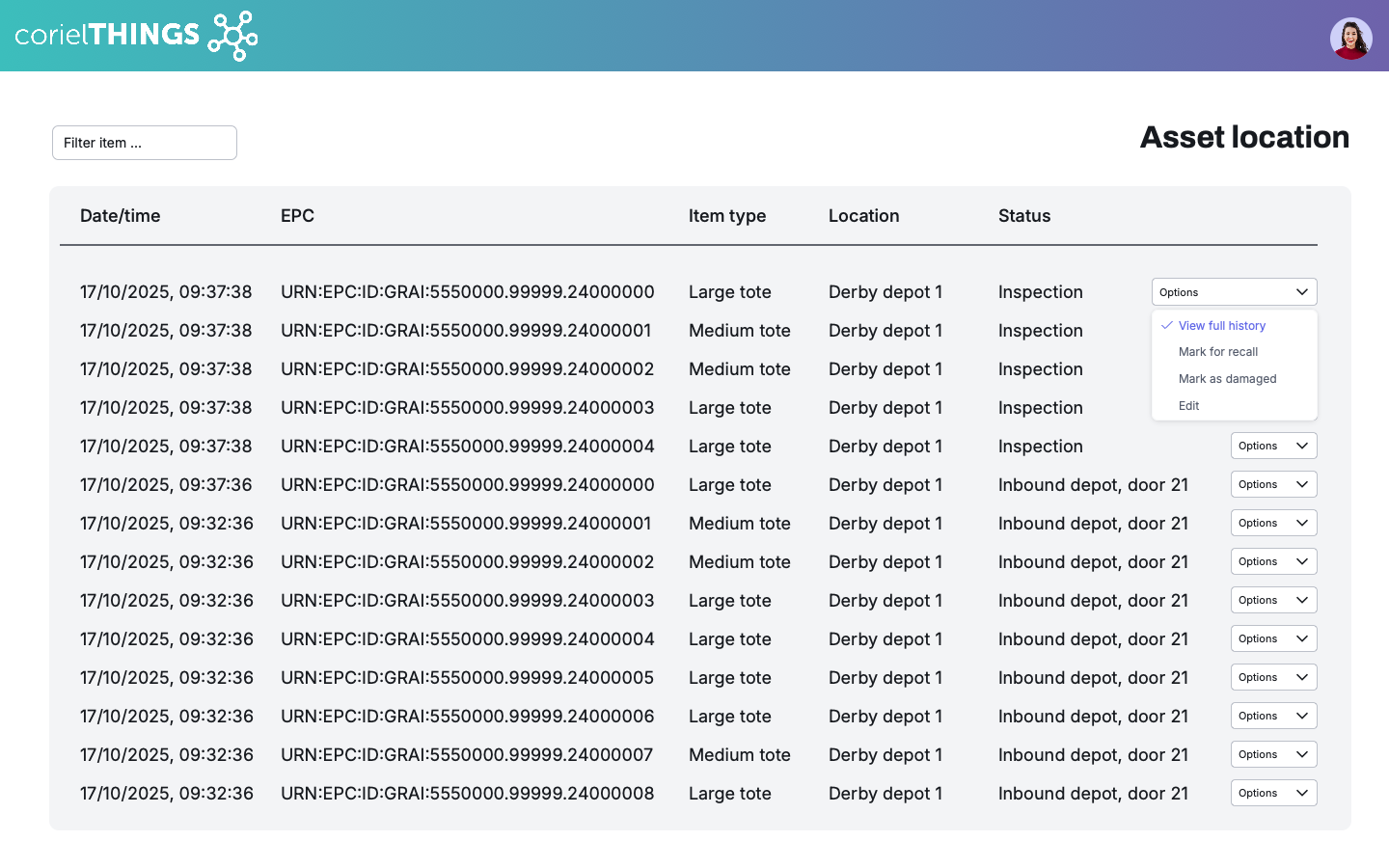

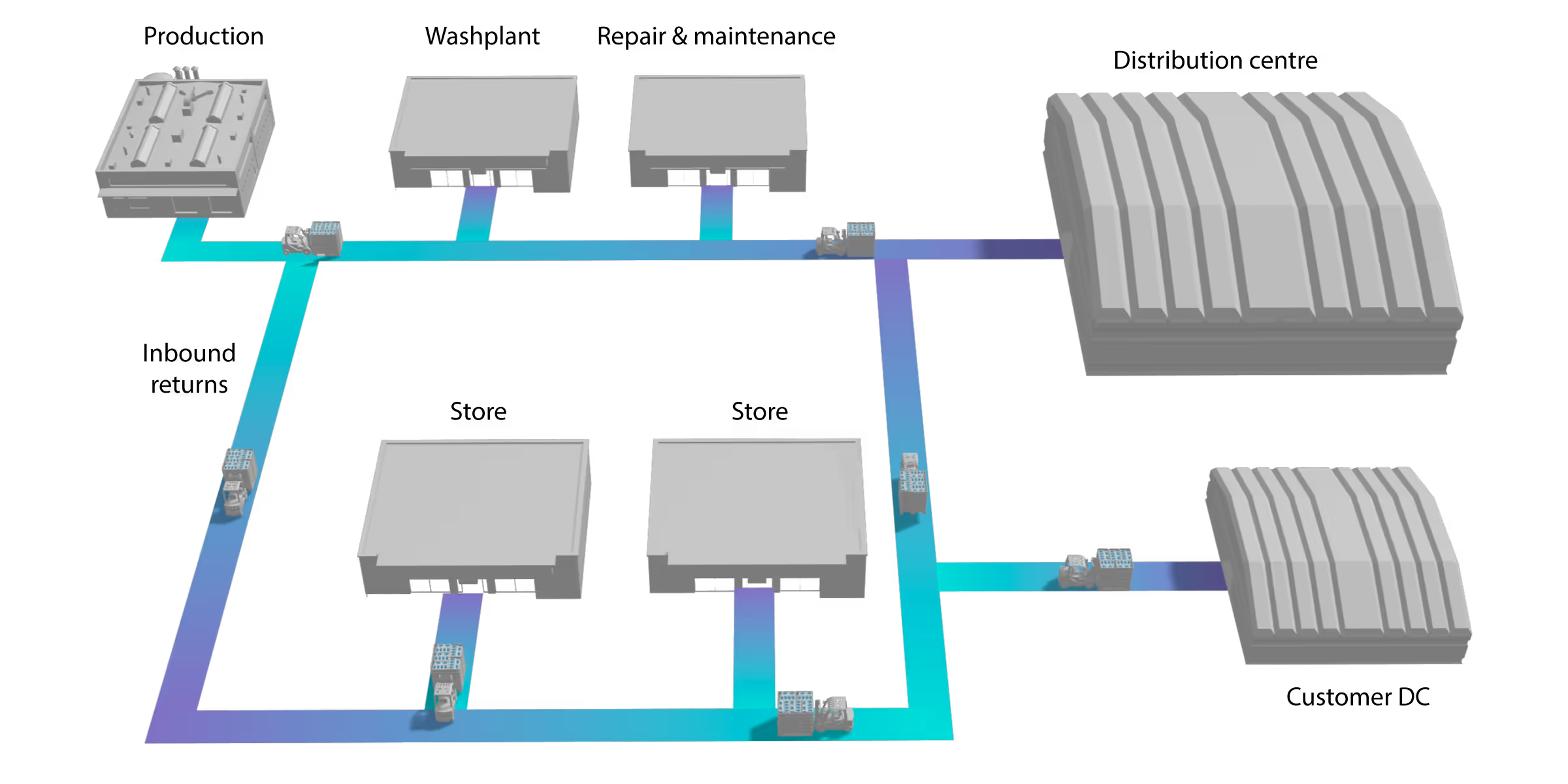

Know where your assets are ...

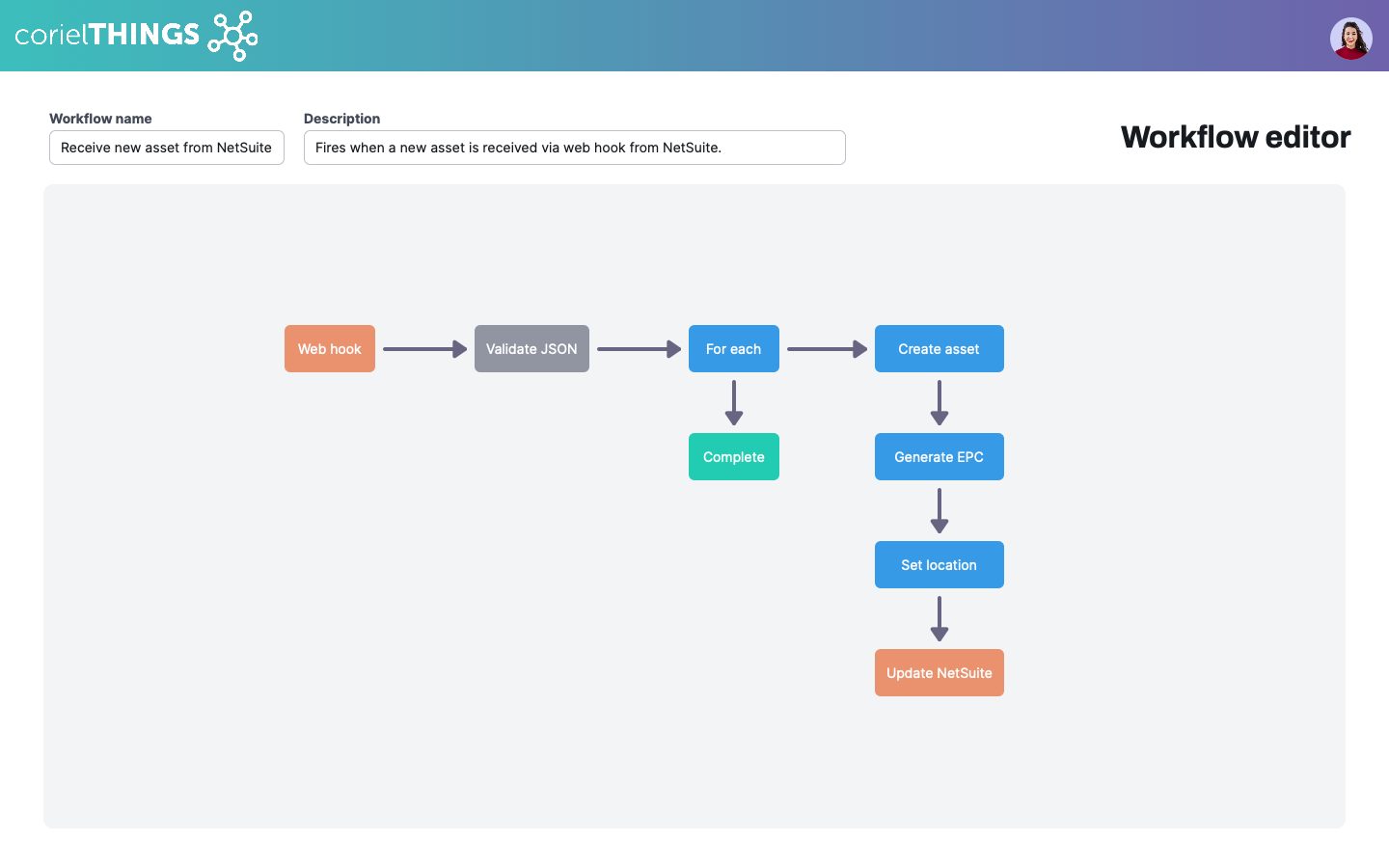

Once your assets are tagged, they can be read at scale and over long distances using a variety of equipment, from handhelds to fully automated conveyor and dock-door systems. The asset’s location and content are immediately updated in your existing ERP/WMS via our platform connector.

- Hands-free/operator free identification of every asset

- Immediate updates to your backend systems

- Know the precise location of every asset

- Micro-location: where is the asset within a site?

- Macro-location: where is the asset within the whole supply chain?

What else can you do with corielTHINGS?

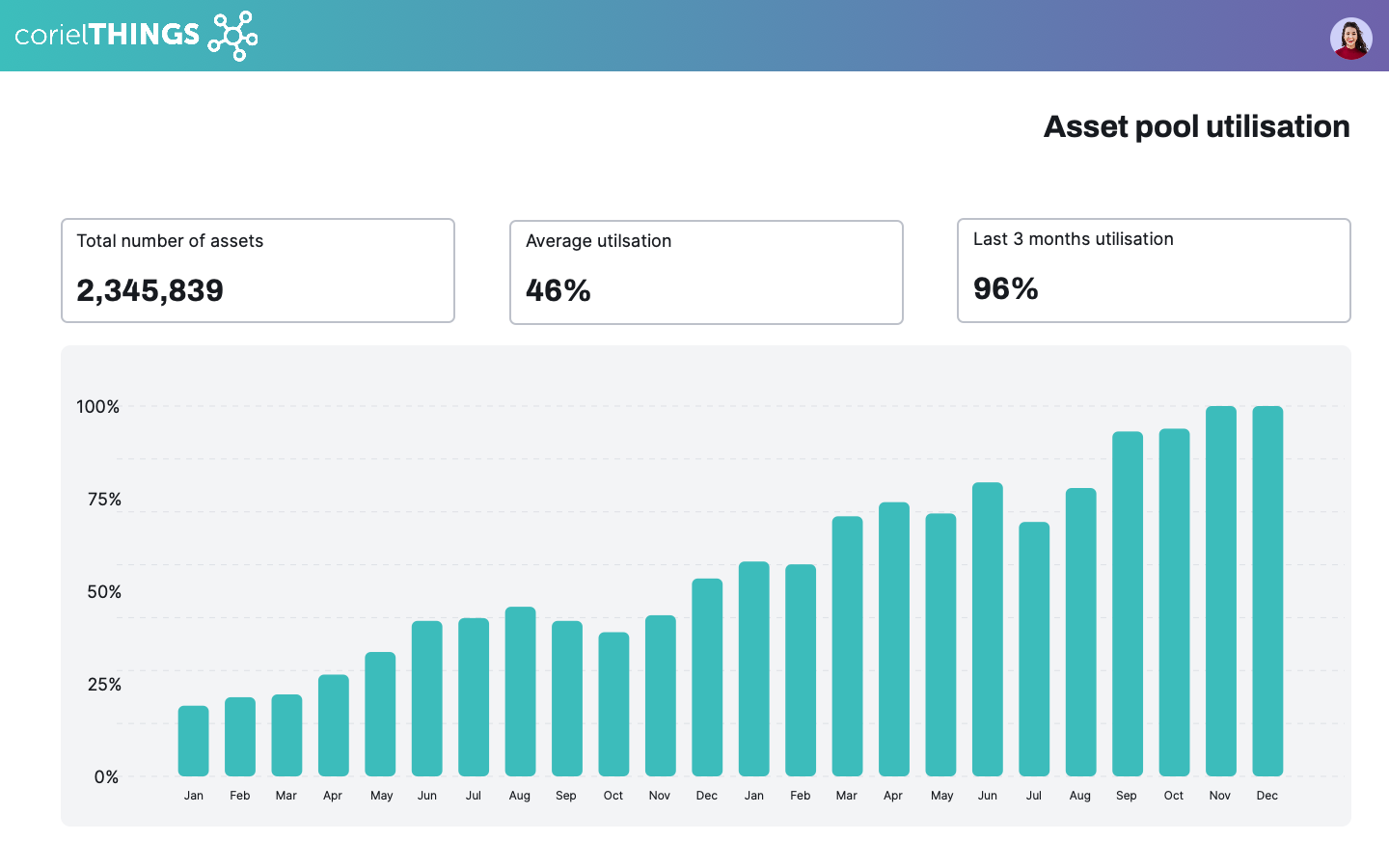

Optimise your utilisation

Simple reports and dashboards give you a ‘birds-eye’ view of what’s happening across your supply chain.

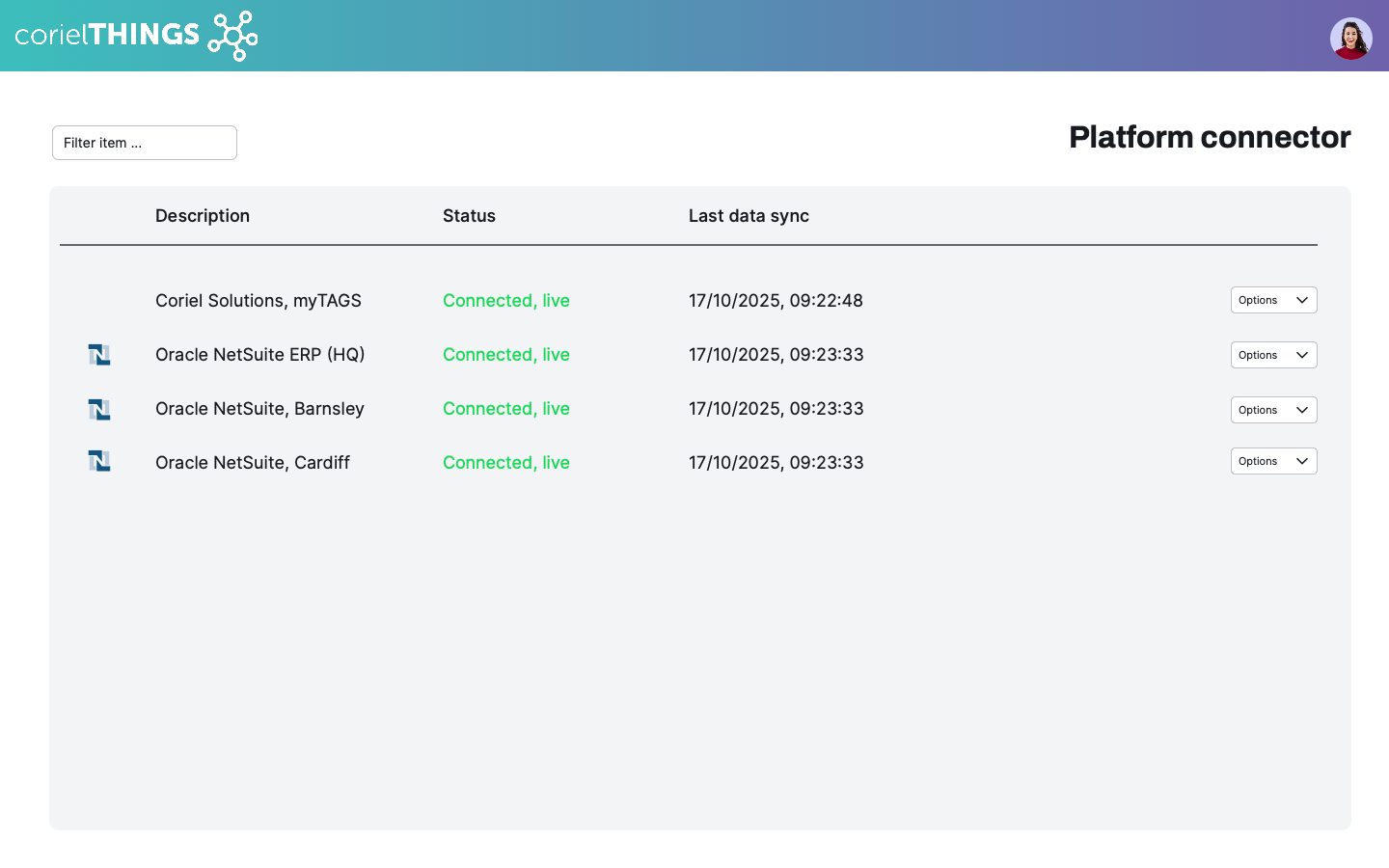

Live sync with your ERP

corielTHINGS is a completely connected platform, allowing you to integrate your ERP, WMS or bespoke systems via simple web calls.

Returnable asset tracking news & content ...

How can RFID integration enhance manufacturing processes?

How can RFID integration enhance manufacturing processes? RFID already powers traceability in the world’s toughest supply chains. In manufacturing, integration turns tags and reads into actionable insight that cuts downtime, improves quality and unlocks true lean...

5 Steps to Successful RFID Label Application

RFID labels play a critical role in accurate asset tracking and inventory management. However, improper application can lead to peeling, poor readability, and even system failures. By following these five essential steps, you can ensure your RFID labels adhere...

Unlocking the future of supply chain logistics with AI and AutoID

Managing your data effectively across the supply chain has long been the holy grail for organisations of all shapes and sizes. With millions of barcodes and RFID tags being read by thousands of data collection devices, the scale of collected data has never been...