RFID solutions for reducing food waste

Item-level RFID, temperature sensing and standards-based data sharing help you cut shrinkage, avoid markdowns, meet legal obligations and prove on-time, in-date delivery across your cold chain.

%

of global retail revenue is lost through food wastage ($540b)

%

of retail busineses say wastage has increased in the last 3 years

%

of retailer think that supply chain collaboration is falling short

%

of retail business leaders see technology as way to reduce food waste

Source: Avery Dennison, Making the Invisible Visible, the $540B Grocery Bill, 2026.

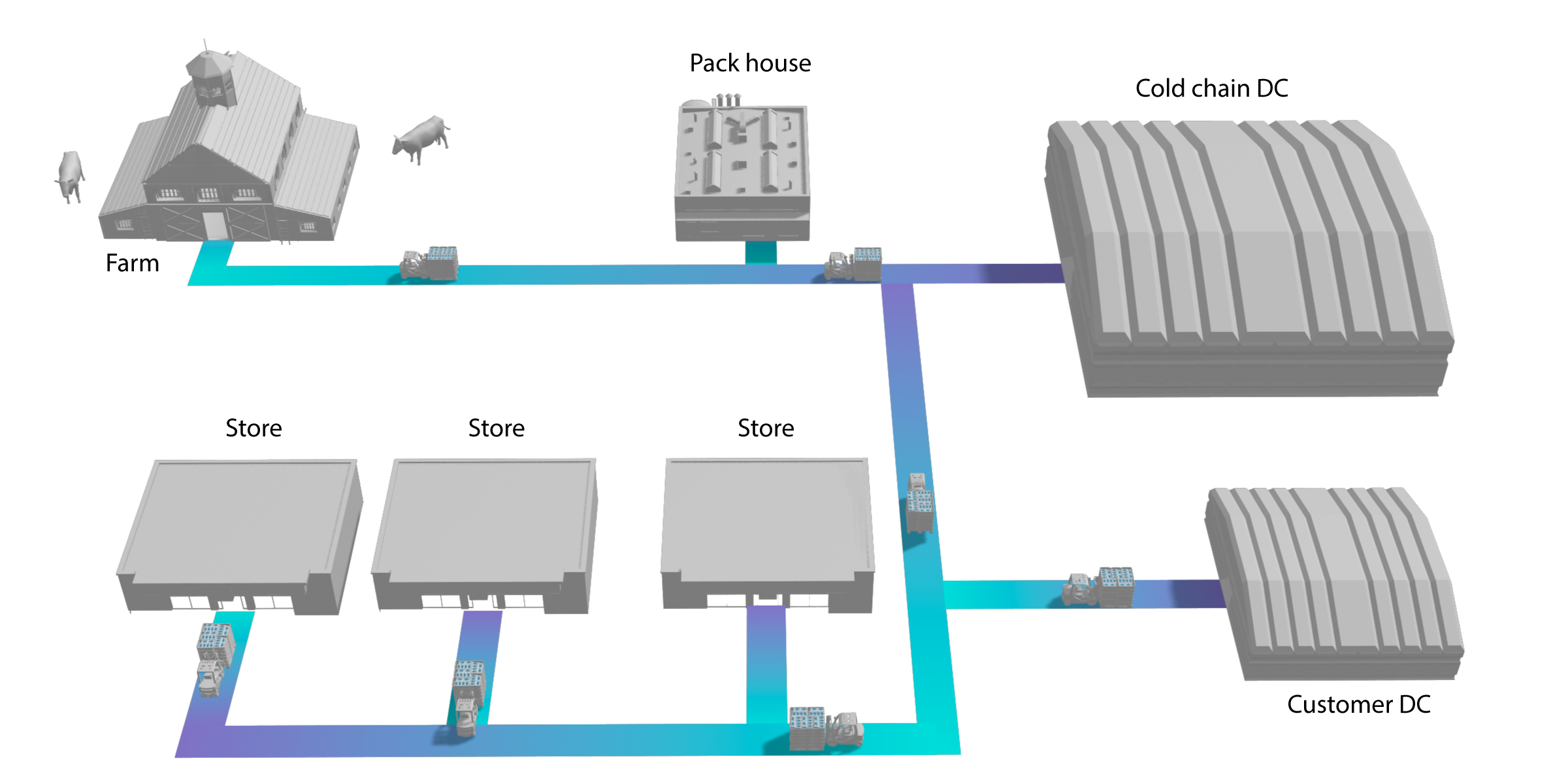

From farm and packhouse to distribution centre, store, and kitchen, item-level RFID labelling and condition sensing provide a real-time view of stock, shelf life, and temperature. Track your returnable assets and items at every handoff to cut out-of-date waste, support compliance and prove on-time, in-date delivery.

Key challenges for the food industry ...

Limited visibility of expiry risk

Stores and distribution centres often rely on manual rotations and fragmented systems, so short-dated items get missed until it is too late.

Inaccurate stock and location data

Barcode-based counts are slow and error-prone, leading to phantom inventory, over-ordering and unnecessary wastage.

Cold-chain blind spots

Without continuous condition monitoring, temperature abuse goes undetected and safe-to-sell decisions become subjective.

Compliance exposure

Misapplied date labels, missing records or weak traceability increase the risk of selling past the use-by date and failing audits.

Weak proof of delivery and custody

Disputes around delivery times, temperatures and remaining life waste time, damage relationships and trigger avoidable write-offs.

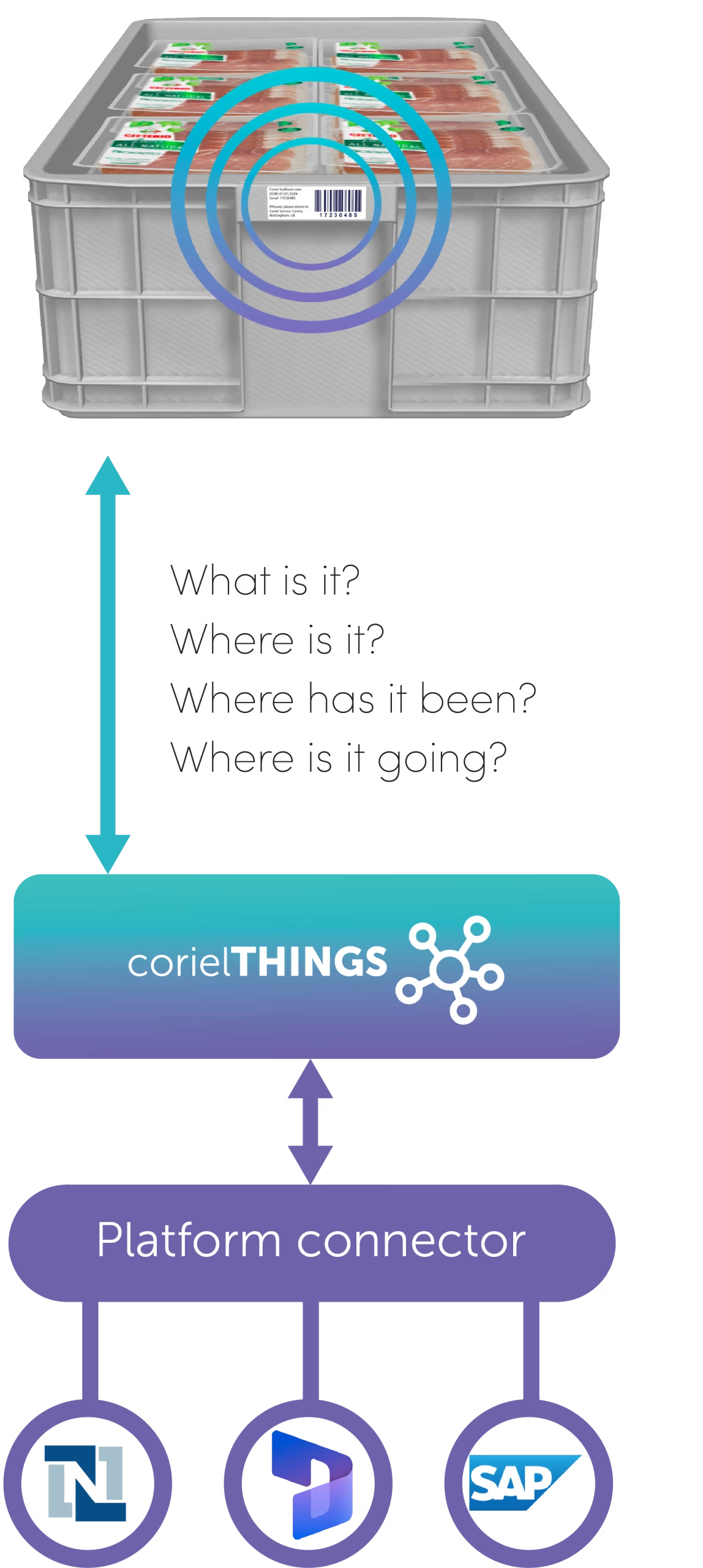

Item-level RFID intelligence

Make every pack speak. With item-level RFID, each product carries a unique digital identity that can communicate its EPC, batch, production data, storage needs and remaining shelf life to readers in stores, depots and vehicles. Unlike line-of-sight barcodes, RFID enables rapid cycle counts, automated exception alerts and accurate back-room to shelf reconciliation. When paired with condition sensors, items can also report temperatures or time-temperature integrations to support decisions that prevent waste. Guidance from global standards bodies ensures the event data is interoperable across your partners.

Complete regulatory compliance ...

Date labelling must be applied correctly and supported by robust records that show storage conditions were maintained. Use-by relates to safety, best before to quality, and both should be paired with clear storage instructions. RFID, combined with sensors and audit-ready logs, strengthens due diligence and simplifies compliance with laws, guidance and industry best practice for date labelling and redistribution.

Ensure you comply with …

- UK Food Information Regulations 2014

- UK Food Safety Act 1990

- Food Safety and Hygiene (England) Regulations

- Regulation (EC) 178/2002 (General Food Law)

- Regulation (EU) 1169/2011 (FIC)

- FDA Product dating policy

- USDA FSIS guidance

Stop out of date wastage ...

Replace guesswork with data. As items approach their use-by date, your system automatically flags them for first-out picking, dynamic repricing or redistribution. Teams see ranked tasks by aisle, bay and product, so the right items move first. Use-by dates are safety limits under law and must be respected; timely identification and action are essential.

- Configure expiry thresholds by category; surface high-risk SKUs first.

- Auto-generate first-out pick lists grouped by aisle to minimise walking.

- Push alerts to handhelds when near-use-by items are detected.

- Trigger dynamic markdowns and step discounts as use-by dates approach.

- Block sale at POS for items past use-by date.

Prove you delivered items on time and within date tolerance

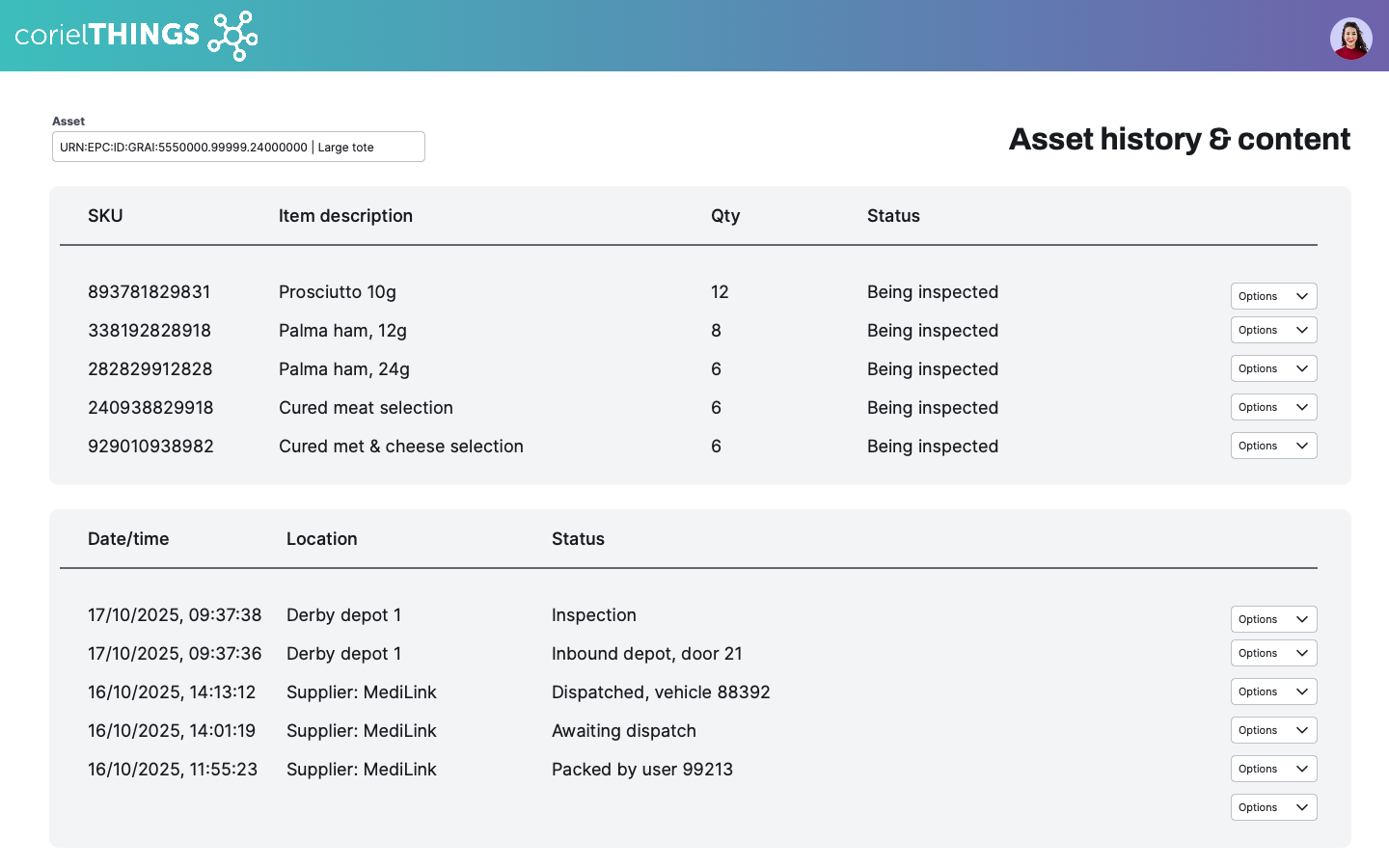

Move from claims to evidence. RFID event data can capture when, where and by whom each item was packed, shipped and received, alongside its remaining shelf life and temperature exposure. Standards such as EPCIS create a shared, trusted chain of custody that resolves disputes quickly, streamlines supplier settlements and prevents unnecessary write-offs.

What else can you do with corielTHINGS?

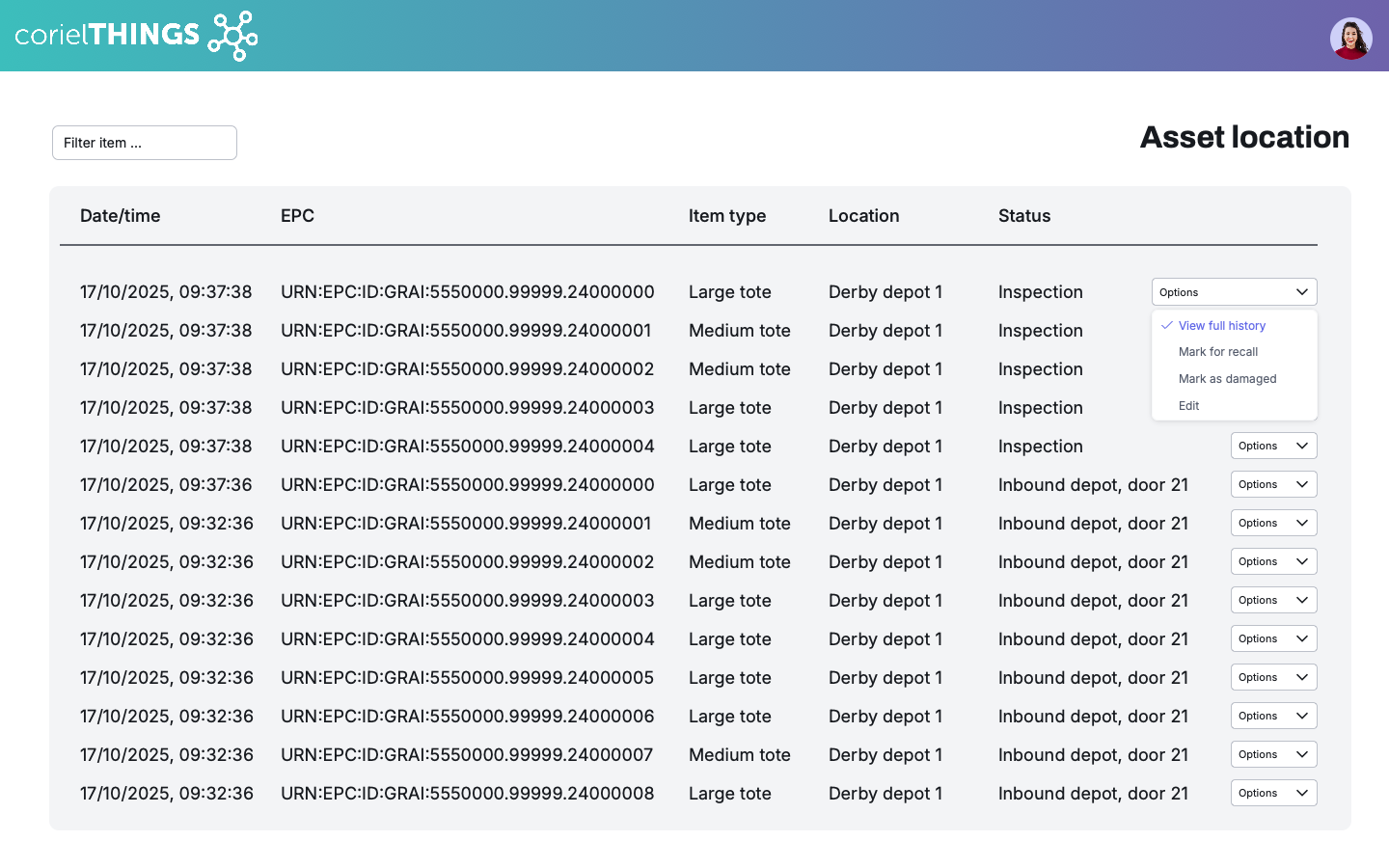

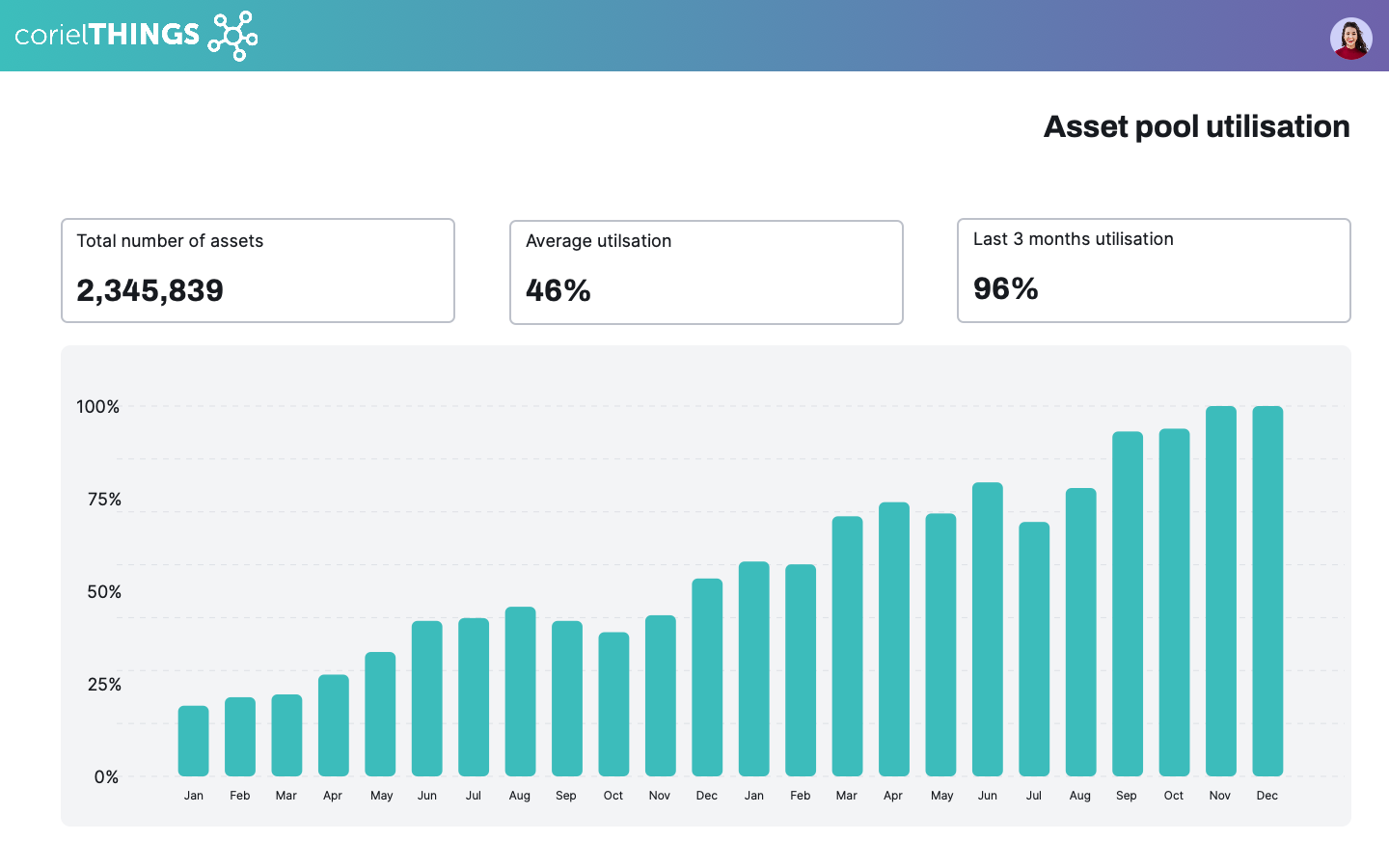

Visualise your supply chain

Simple reports and dashboards give you a ‘birds-eye’ view of what’s happening across your supply chain.

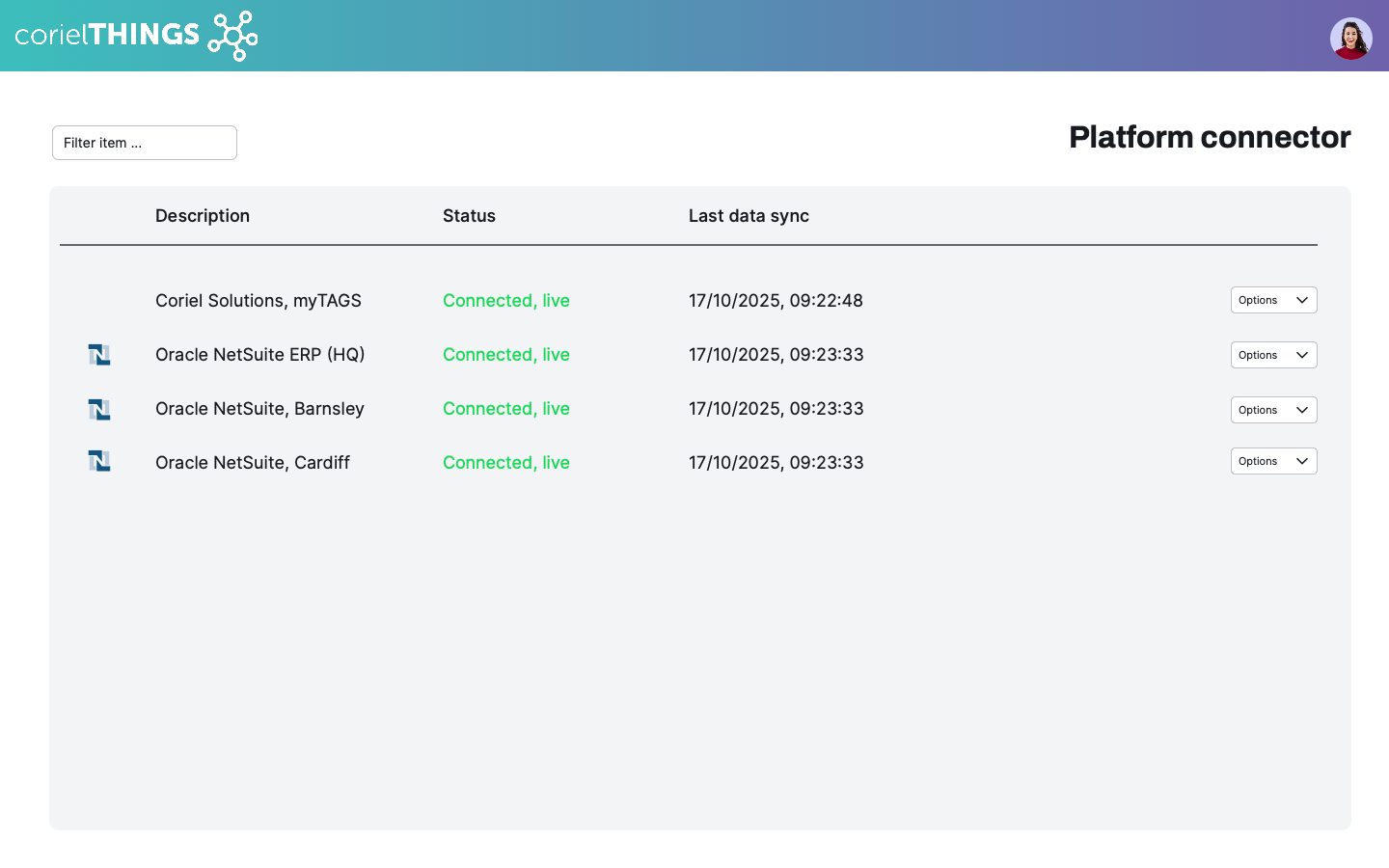

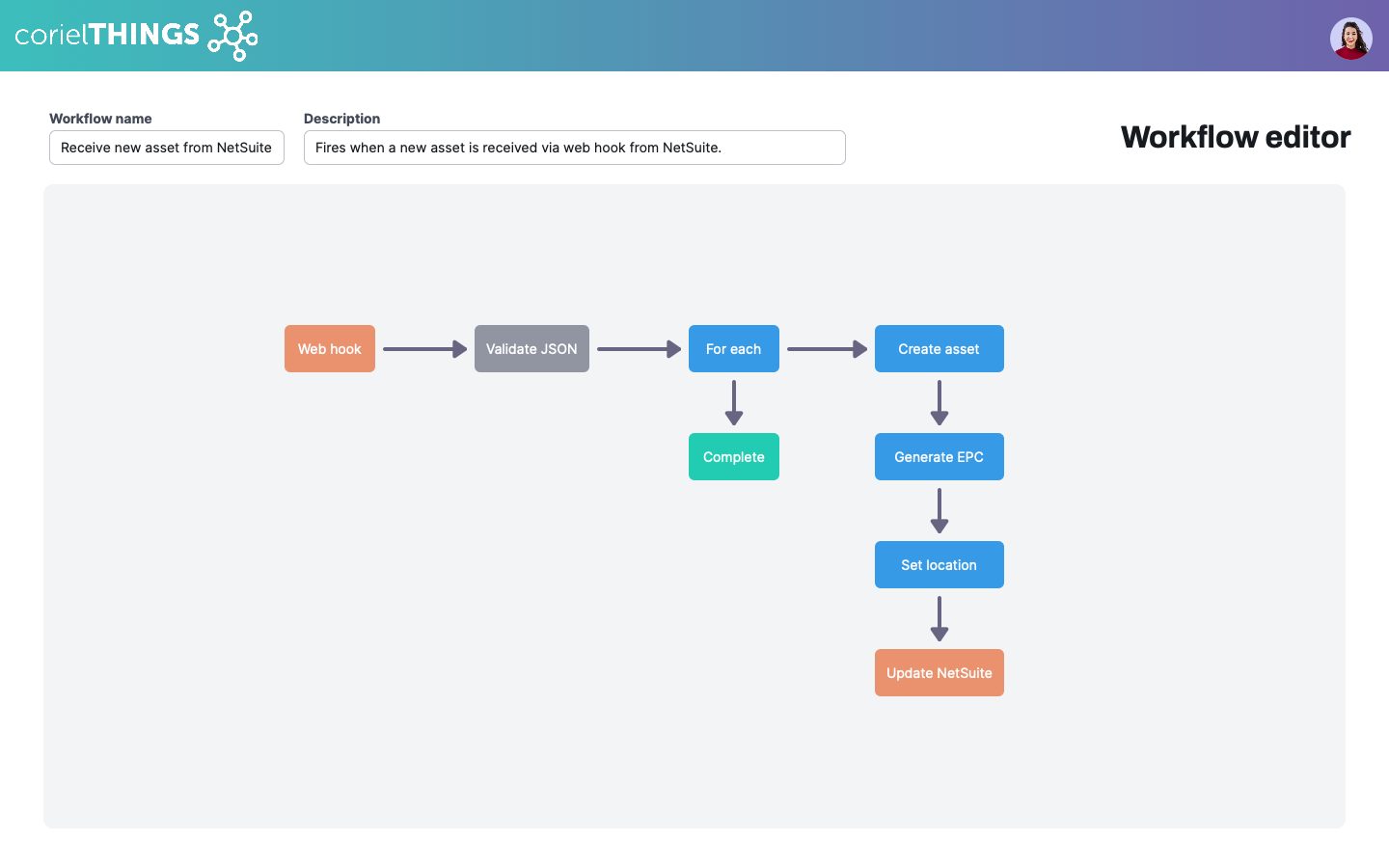

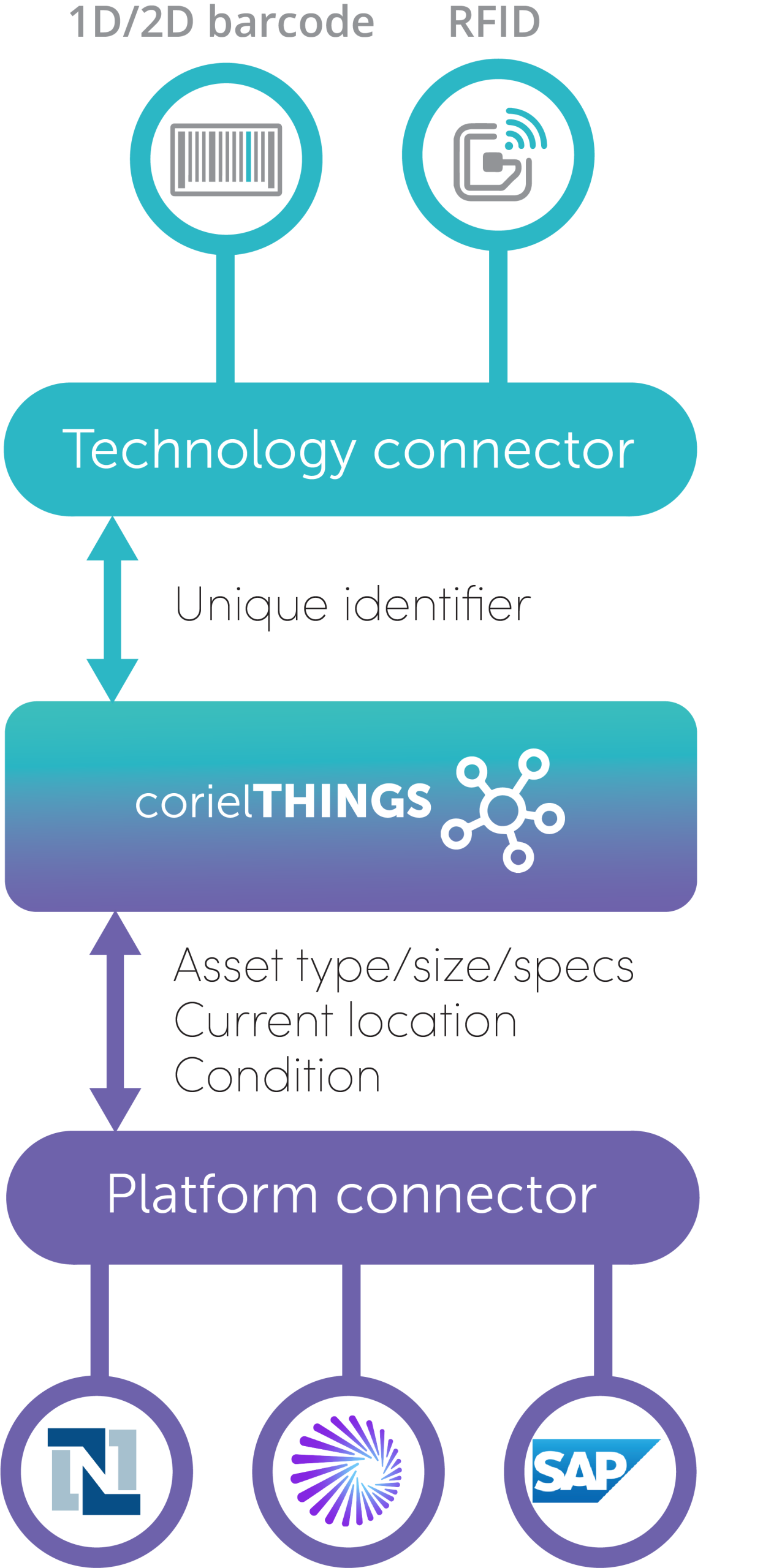

Live sync with your ERP

corielTHINGS is a completely connected platform, allowing you to integrate your ERP, WMS or bespoke systems via simple web calls.

Food waste news & content ...

Tosca selects Mojix and Coriel to implement RFID-based traceability for their reusable containers

PRESS RELEASE Combined expertise and technology enable Tosca to benefit and to provide their end customers with reliable end-to-end traceability for Returnable Plastic Containers, improving stock accuracy between all Tosca maintenance sites in Europe. Los Angeles,...

The importance of Proof of Concepts for Auto ID projects

First things first, what is Auto ID? Auto ID is a method of automatically identifying objects, collecting data about them, potentially interacting with them, and connecting them directly to computer systems. This is all completed (largely) without human involvement...

What is RFID and how has it changed over the past 25 years?

What is RFID? RFID or Radiofrequency Identification, a technology first used in World War two is one of the fastest growing technologies in the world with an expected market of over 12 billion Dollars in 2021, but what is it really? Well, these days, we use RFID...

Useful links

Data on the impact of reducing food waste, from over 3,500 global retailer leaders across 7 countries

Food waste in the UK

A 2024 research study from the UK Parliment

Food waste in Europe: facts, EU policies and 2030 targets

Food waste costs the EU over €130 billion each year and affects millions of households. Find out the causes, the impact and the EU actions simply explained.