Barcode & RFID track & trace for the oil & gas supply chain

Industrial track and trace solutions that work from wellhead to warehouse. Barcode, RFID, and IoT solutions that identify parts, pipes, tools, and containers in harsh oil and gas environments.

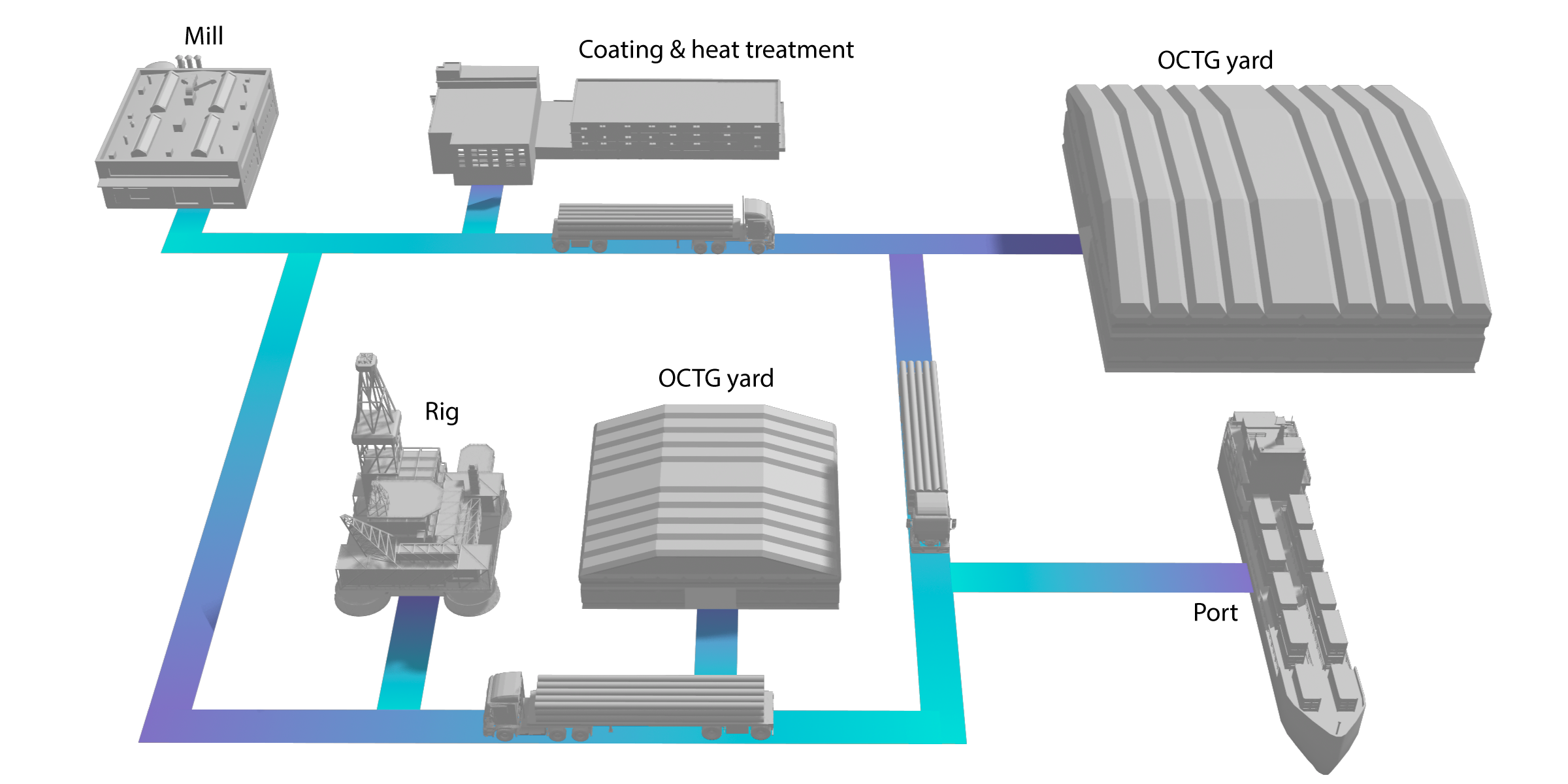

From pipe mills and Oil Country Tubular Goods (OCTG) yards to fabrication shops, platforms and refineries, Coriel Solutions delivers end-to-end identification and data capture, so you always know what you have, where it is, and its complete usage history. By combining rugged RFID solutions, accurate barcode solutions and secure IoT solutions, we enable hands-free identification, instant lookup of certificates and maintenance records, and a full, auditable chain of custody for every asset.

Key challenges for the oil & gas supply chain ...

Safety, compliance and audit trail

Safety-critical assets must be uniquely identified and linked to accurate documentation. Our systems create a trusted digital history for every item, simplifying inspections, incident investigations and regulator audits.

Harsh environments and metal assets

Steel pipes, valves and tools are difficult to identify due to their metal content. We select the right tag types and readers, then optimise placement and shielding so assets can be read reliably in metal-dense, hazardous locations.

Lost time and poor utilisation

High-value tools and spares are often misplaced between workshops, laydown yards and offshore sites. Automated portals, handhelds and vehicle-mounted readers update locations in real time, cutting search time and improving utilisation.

Counterfeit risk and warranty control

Assure that critical components are genuine and within warranty. Each asset is tied to its certificates and product data, so teams can verify authenticity, check warranty status and confirm correct specification before use.

Turnaround & logistics complexity

During shutdowns and turnarounds, throughput and accuracy matter. Bulk read at gates and dock doors, maintain live inventories of pipes and skids, and capture proof of movement and delivery without manual scanning.

Make all your assets intelligent ...

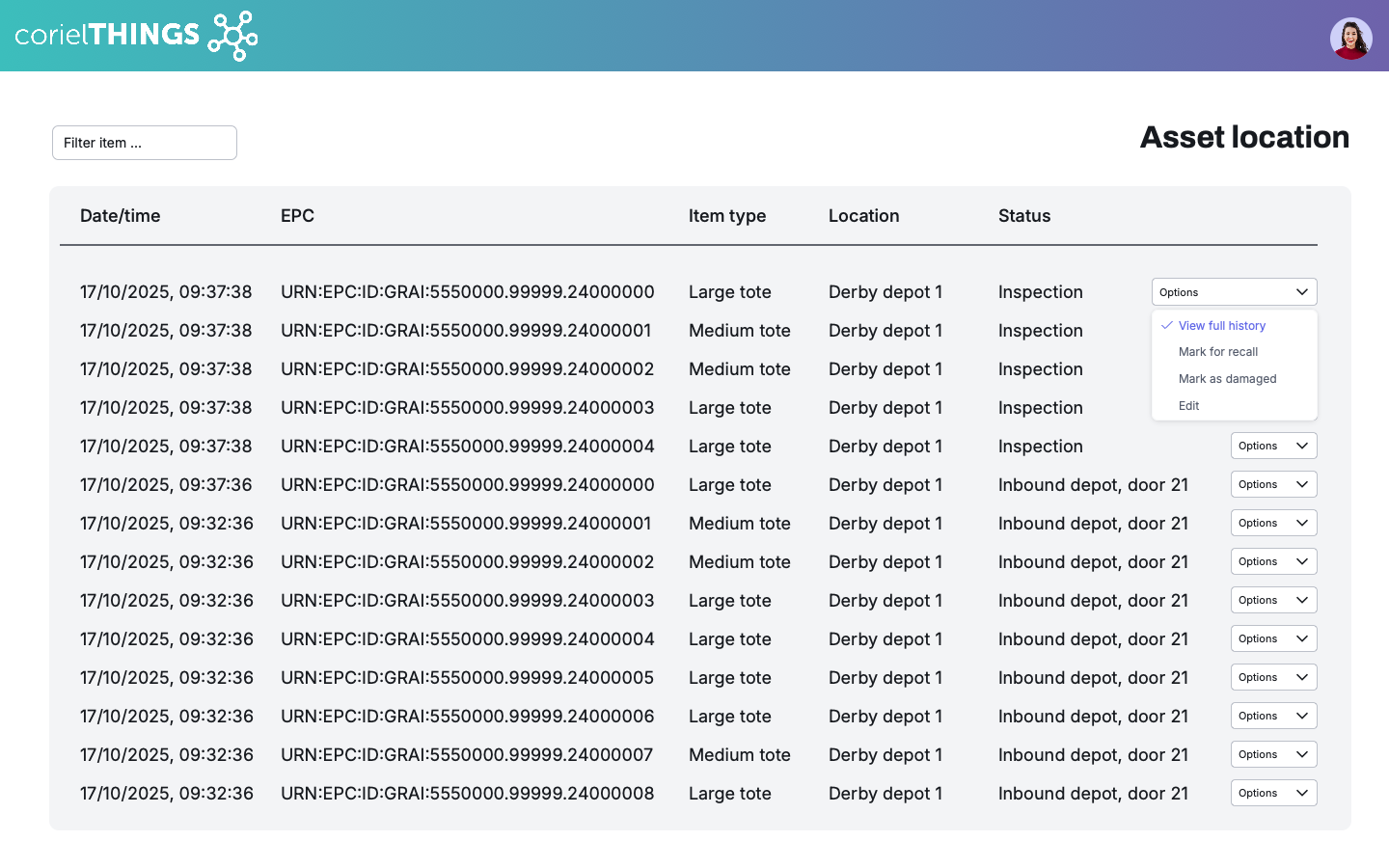

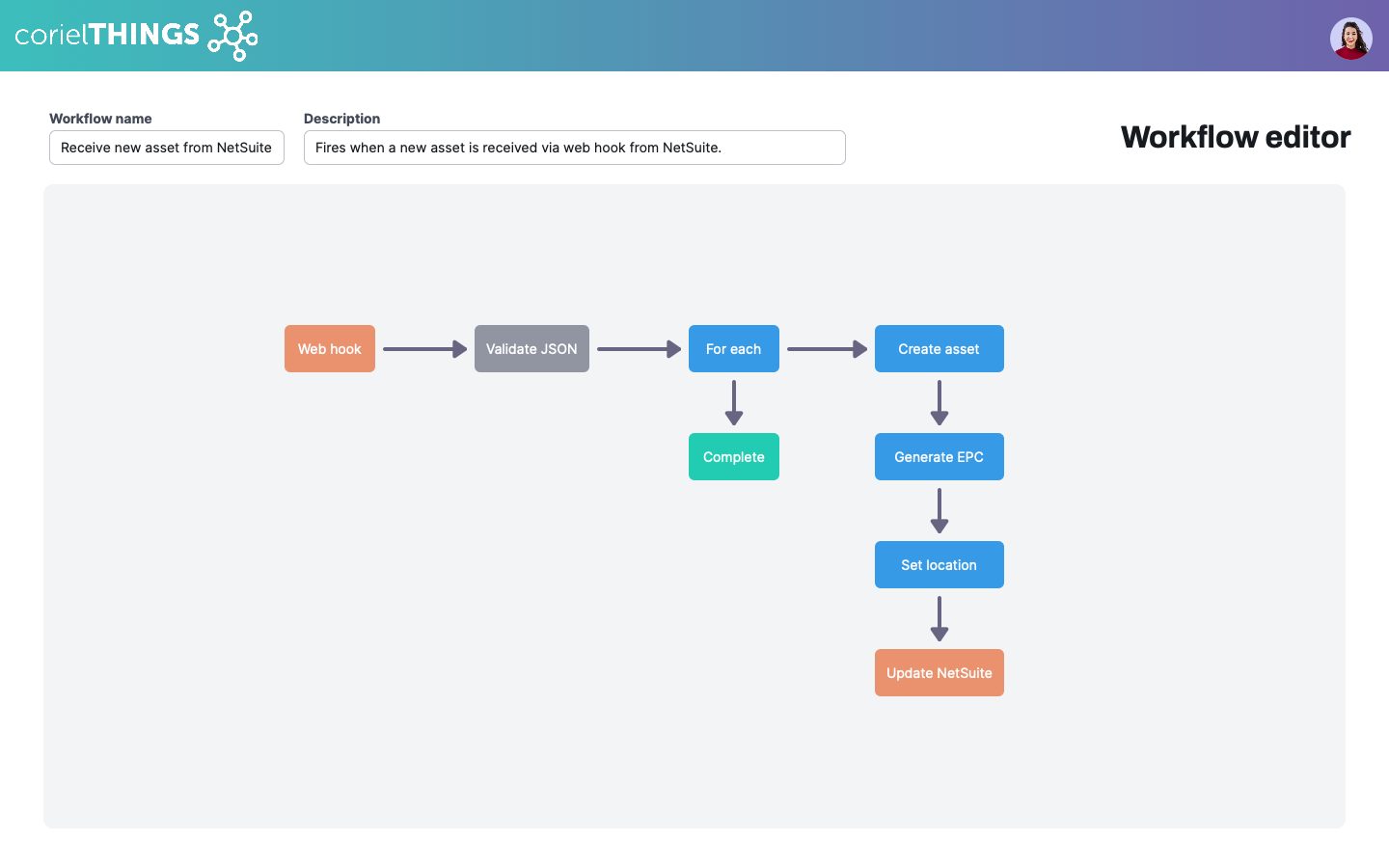

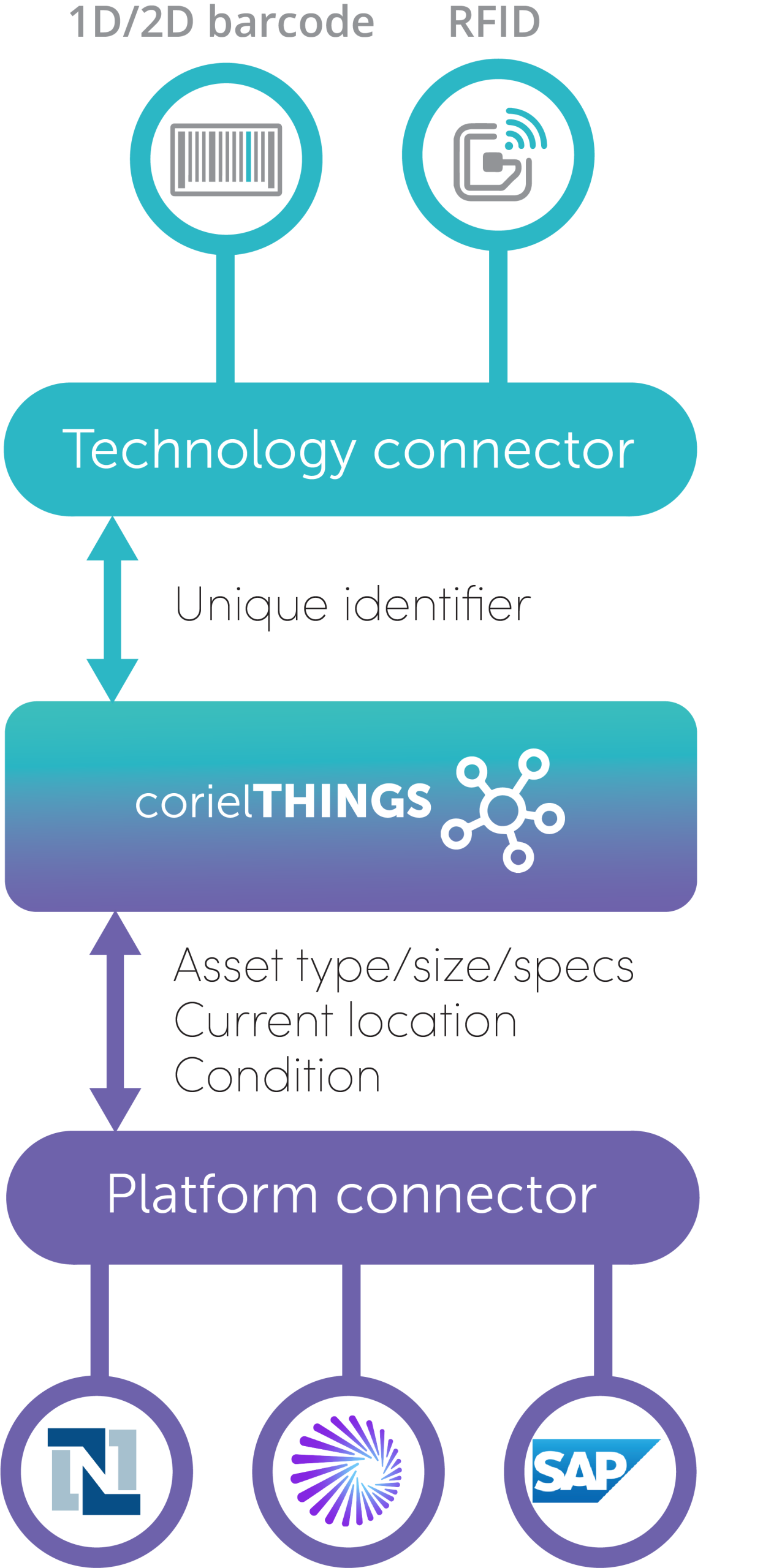

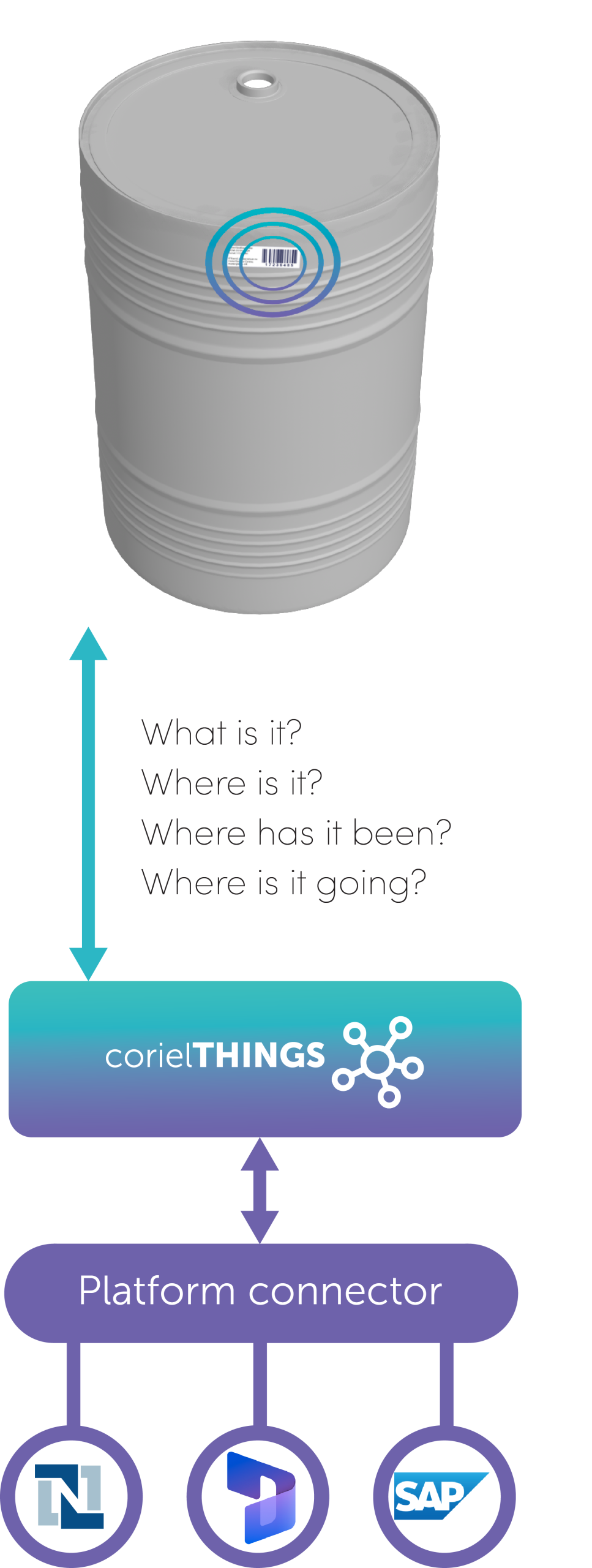

corielTHINGS creates and manages GS1 and EPC-compliant barcodes, QR codes and RFID tags, building a unique digital identity for each asset. That identity links to certificates, drawings, pressure test records and service history, making critical information available to authorised users on any device.

- Track precise location across yards, warehouses and offshore sites

- Associate assemblies and contents for full item-level traceability

- Manage inspection, calibration and cleaning tasks

- Monitor contractor and partner usage of assets

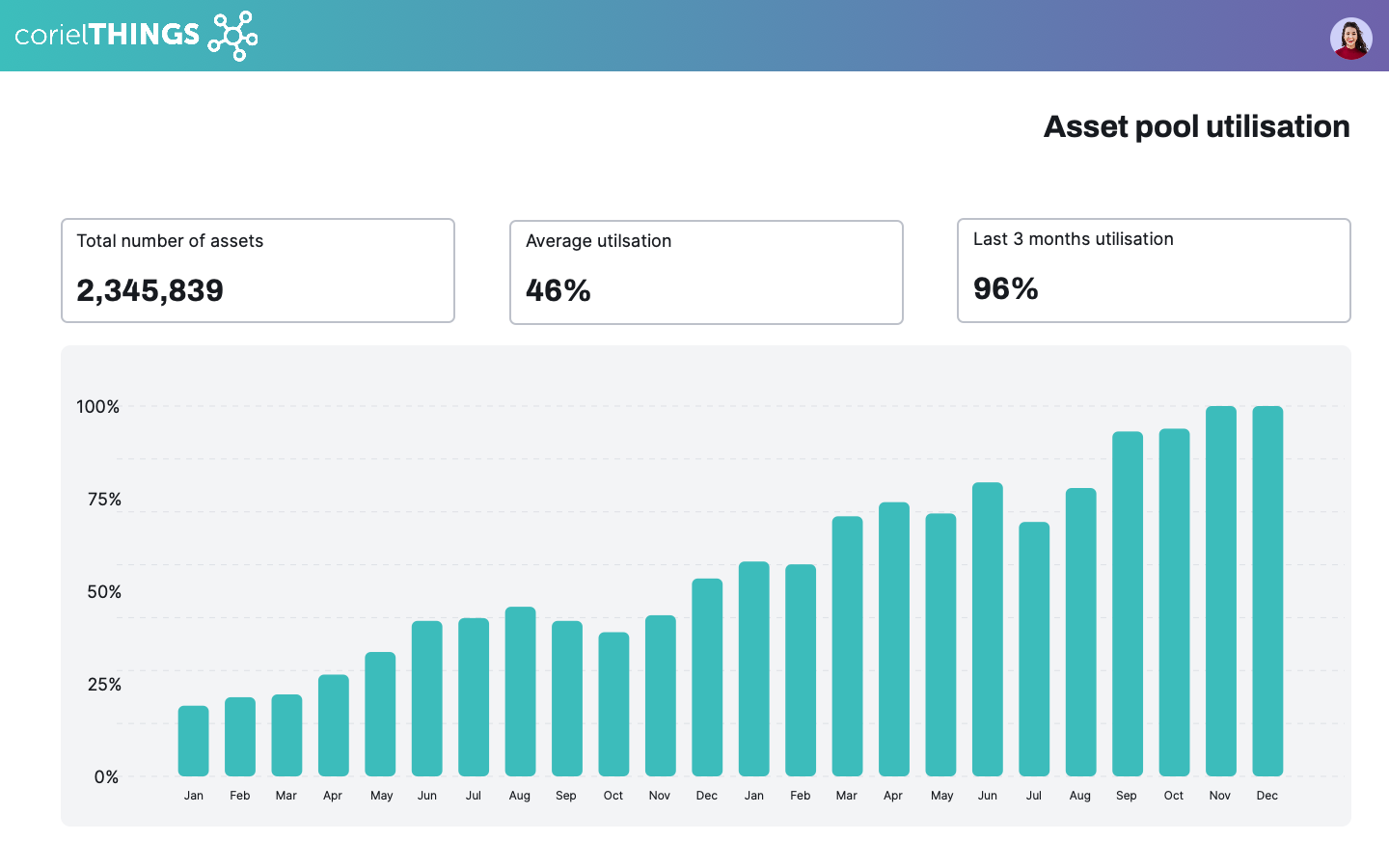

- Optimise the utilisation and lifecycle of your asset pool

Assured compliance, simple reporting ...

Accurate monitoring of assets and their contents makes regulatory adherence straightforward. Serial numbers, heat numbers, batch data, storage conditions and a complete movement history are all handled in one place. Simple dashboards and exports support regulator requests and internal audits without time-consuming manual collation.

- Complete, auditable trail of movements and contents

- Current and historic asset status, owners and locations

- Proof of packing, dispatch, receipt and installation

- Asset condition, inspection and calibration history

- Role-based access to drawings, certificates and procedures

Know where your product and tools are ...

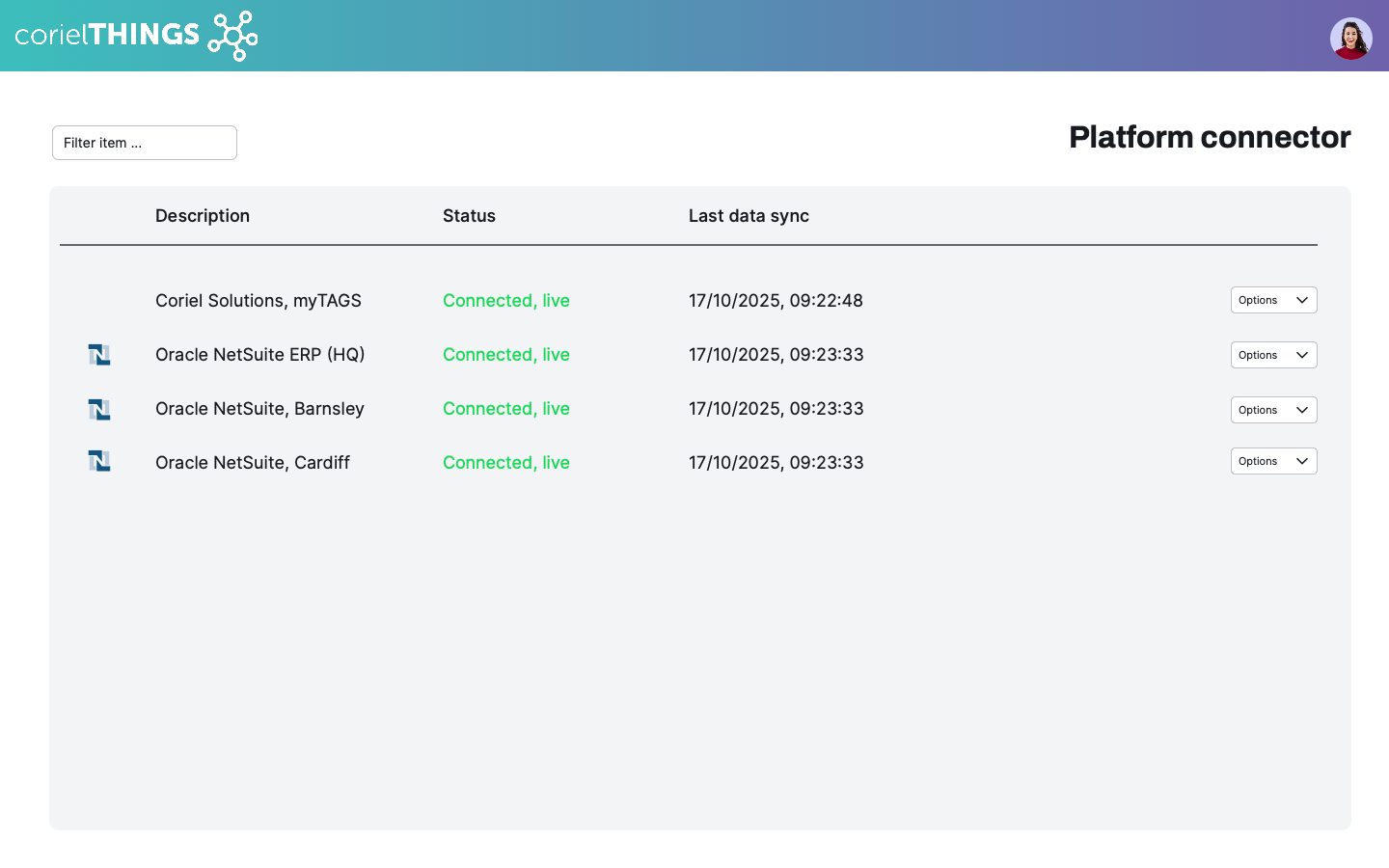

Once tagged, assets can be read at scale and at speed using handhelds, vehicle-mounted readers, portals and conveyor systems. Locations update immediately in your existing ERP, EAM or WMS via our platform connector, providing one version of the truth across operations.

- Hands-free, operator-free identification at control points

- Immediate updates to your backend systems

- Micro-location within a site and macro-location across the network

- Exception alerts for unauthorised moves and late returns

What else can you do with corielTHINGS?

Visualise your supply chain

Simple reports and dashboards give you a ‘birds-eye’ view of what’s happening across your supply chain.

Live sync with your ERP

corielTHINGS is a completely connected platform, allowing you to integrate your ERP, WMS or bespoke systems via simple web calls.

Typical oil & gas use cases ...

Tubular traceability

Track pipes, casing and OCTG from mill to rig with item-level IDs and a complete movement history.

Component identification

Intelligently tag: valves, spools, skids and assemblies to link parts to drawings, specs and certificates.

Point-of-use certification

Surface certificates and inspection records on site for faster QA and safety checks.

Turnaround logistics

Use bulk reads at gates and dock doors to speed receipts and dispatch during shutdowns.

Oil & gas news & content ...

How can RFID integration enhance manufacturing processes?

How can RFID integration enhance manufacturing processes? RFID already powers traceability in the world’s toughest supply chains. In manufacturing, integration turns tags and reads into actionable insight that cuts downtime, improves quality and unlocks true lean...

Unlocking the future of supply chain logistics with AI and AutoID

Managing your data effectively across the supply chain has long been the holy grail for organisations of all shapes and sizes. With millions of barcodes and RFID tags being read by thousands of data collection devices, the scale of collected data has never been...

The importance of Proof of Concepts for Auto ID projects

First things first, what is Auto ID? Auto ID is a method of automatically identifying objects, collecting data about them, potentially interacting with them, and connecting them directly to computer systems. This is all completed (largely) without human involvement...

Useful links

Learn more about our project with ITECO Oil Field Supply