Automatic Vehicle Identification for the rail & freight industry

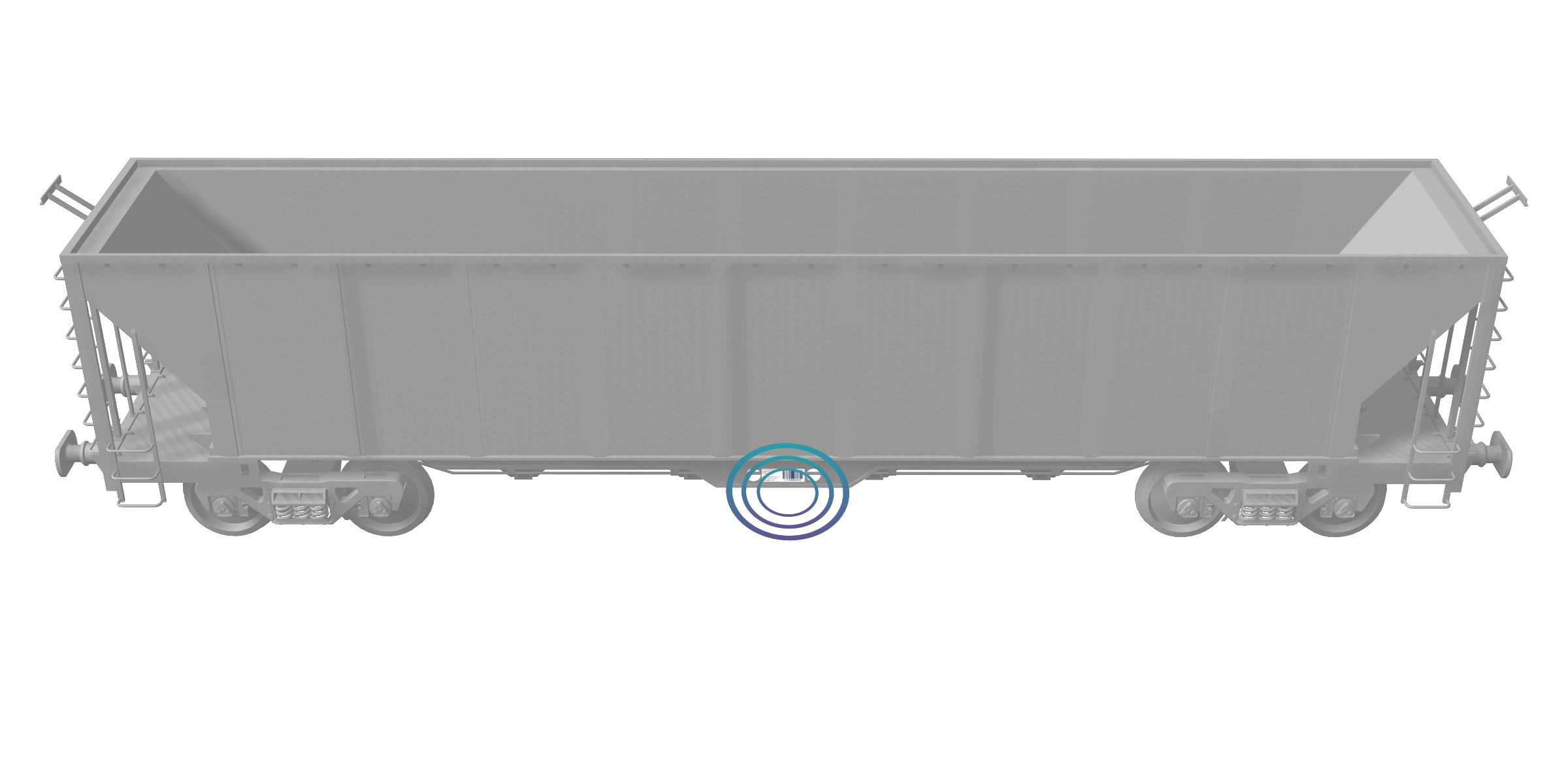

RFID, barcode, and IoT solutions that capture events when rolling stock enters defined assets, such as inspection portals, wash plants, and depots for maintenance, warranty and operational reporting.

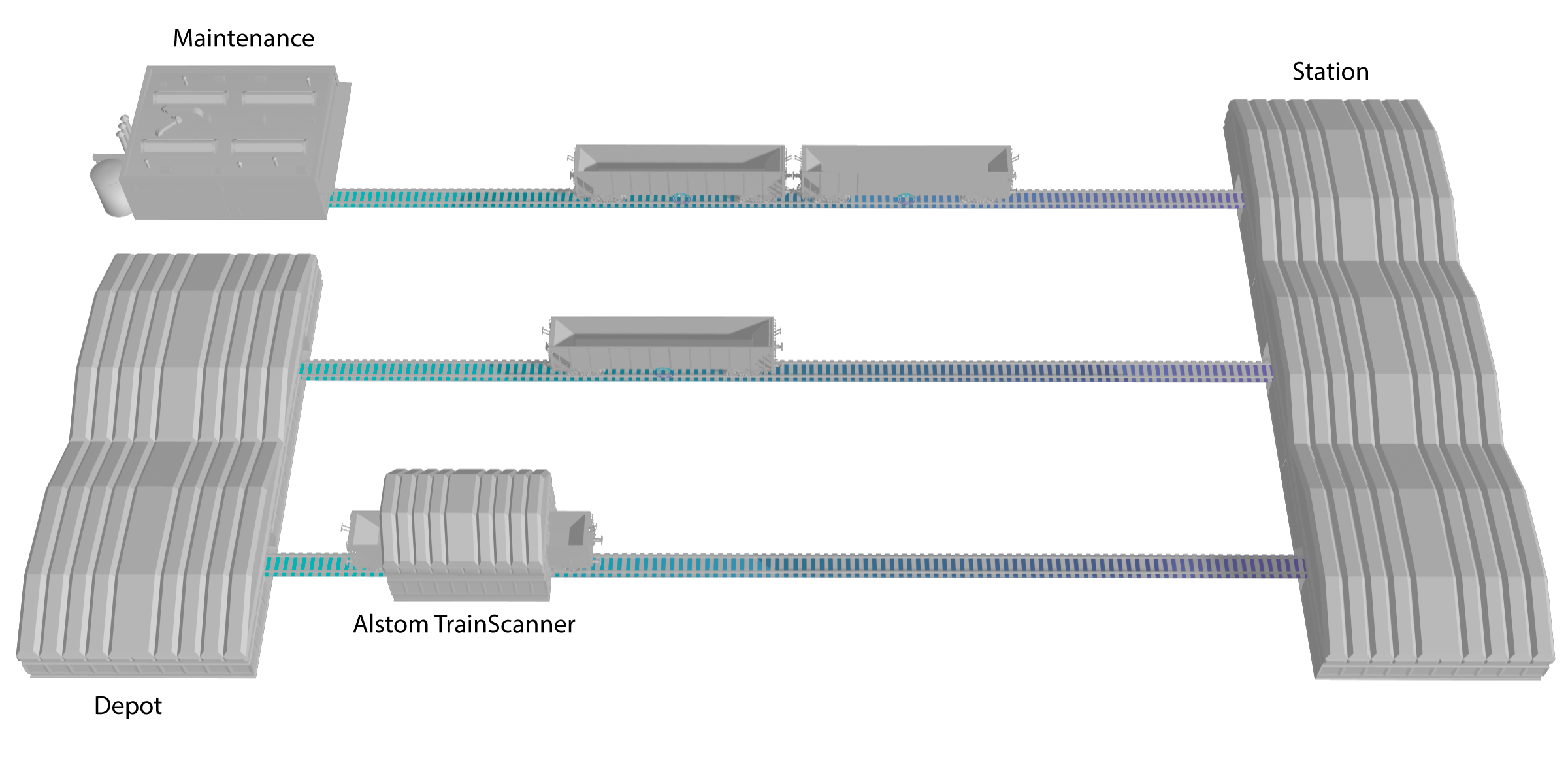

Rail operations need certainty at the moments that matter. Rather than tracking trains across the entire network, our approach focuses on using automatic vehicle identification at controlled locations. When a vehicle passes a wayside scanner, enters an inspection portal such as TrainScanner, arrives at a depot gate or rolls through a wash plant, the system reads its identity automatically and records the event to a single, trusted history. That history supports maintenance scheduling, warranty validation and accurate service records without manual scanning.

Key challenges for the rail industry ...

Asset visibility at scale

Rail operators manage tens of thousands of wagons, bogies and components, often spread across networks, depots and borders, making accurate, real-time asset visibility extremely difficult.

Identification in harsh environments

Rolling stock and freight assets face vibration, weather, dirt and impact, causing labels or identifiers to degrade, fail or become unreadable long before asset end-of-life.

Maintenance & safety assurance

Maintenance must be timely, traceable and compliant, as missed inspections or incorrect component histories directly increase safety risk, downtime and the likelihood of serious incidents.

Traceability during incidents and recalls

When failures occur, operators must rapidly identify affected vehicles, components or batches, isolating risk without grounding entire fleets or disrupting services unnecessarily.

Integration and governance

Asset identification data must integrate cleanly with maintenance, safety and ERP systems, ensuring trusted records, controlled access and audit-ready reporting across multiple operators and suppliers.

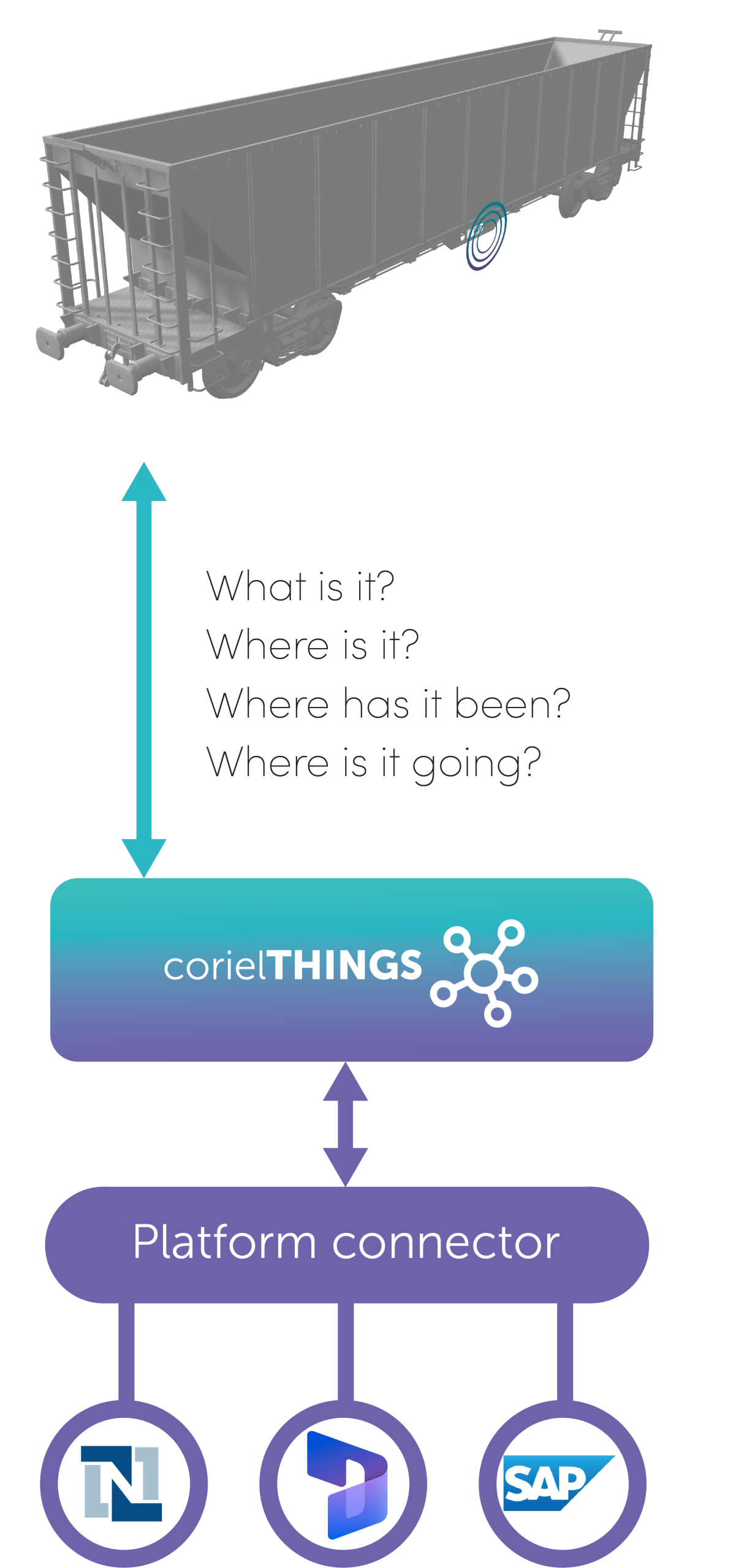

Make all your vehicles and loads intelligent …

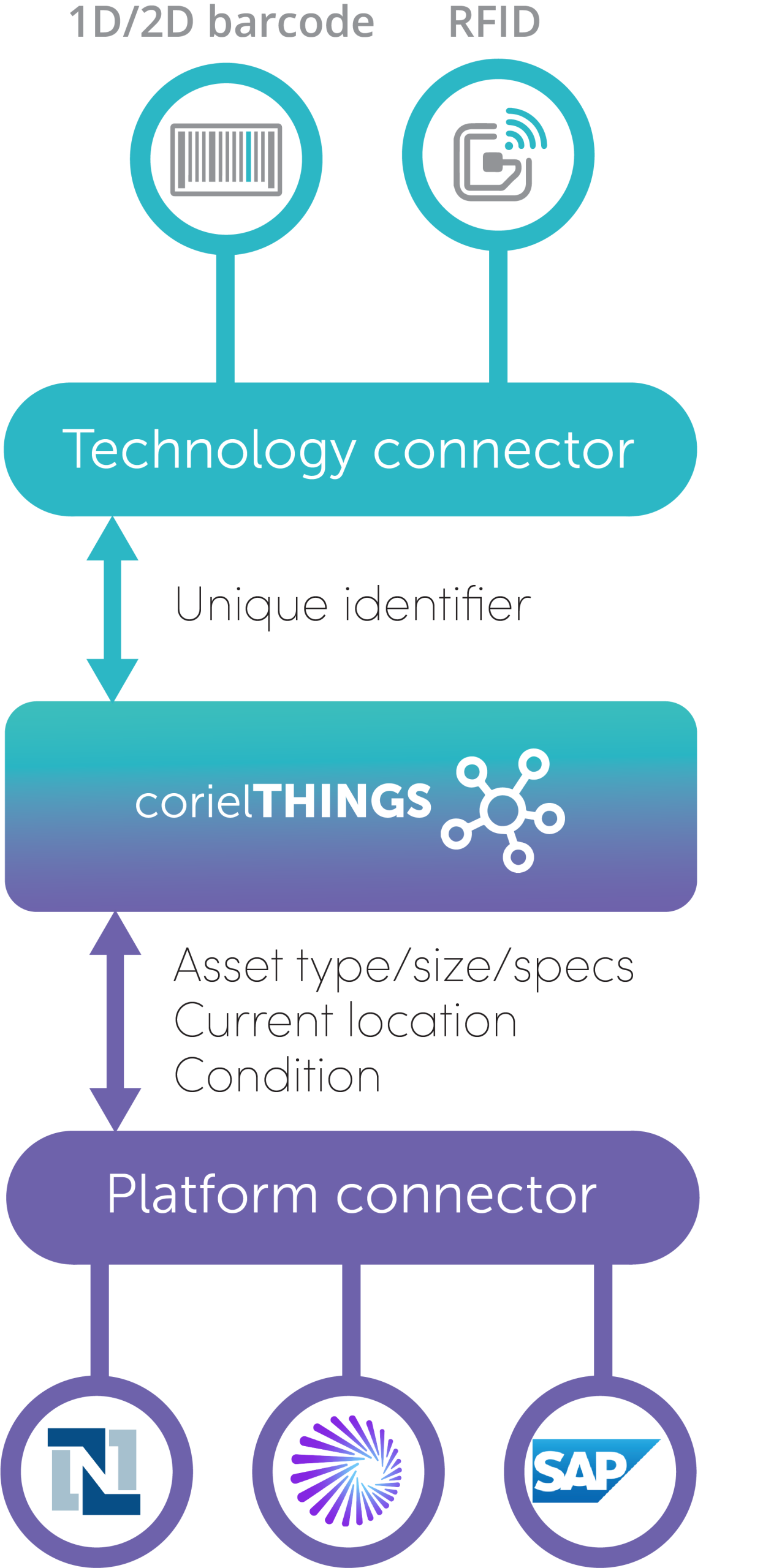

The Coriel Solutions automatic vehicle identification system uses durable UHF RFID tags linked to a unique digital record. Each record contains fleet master data, maintenance rules and load information. The result is a trusted digital identity for every vehicle, container and part that downstream systems can act on.

- Identify vehicles and loads at portals, depot gates and terminal lanes

- Maintain last-seen location at defined set points

- Associate containers and swap bodies to wagons

- Attach certificates, damage reports and images to records

- Provide role-based access on mobile and desktop

Assured compliance and simple reporting …

Accurate automatic vehicle identification event capture makes adherence to standards and internal policies straightforward. Serial numbers, fleet identifiers and load IDs are stored with time and place. Dashboards and exports simplify reporting to stakeholders while keeping a full audit trail.

- Complete, auditable trail of arrivals, departures and inspections

- Consistent identities across partners and leased stock

- Evidence for safety, access charge and performance reporting

- Configurable retention aligned to governance policies

- Support for EPC and GS1 data formats

Automatic Vehicle Identification in action ...

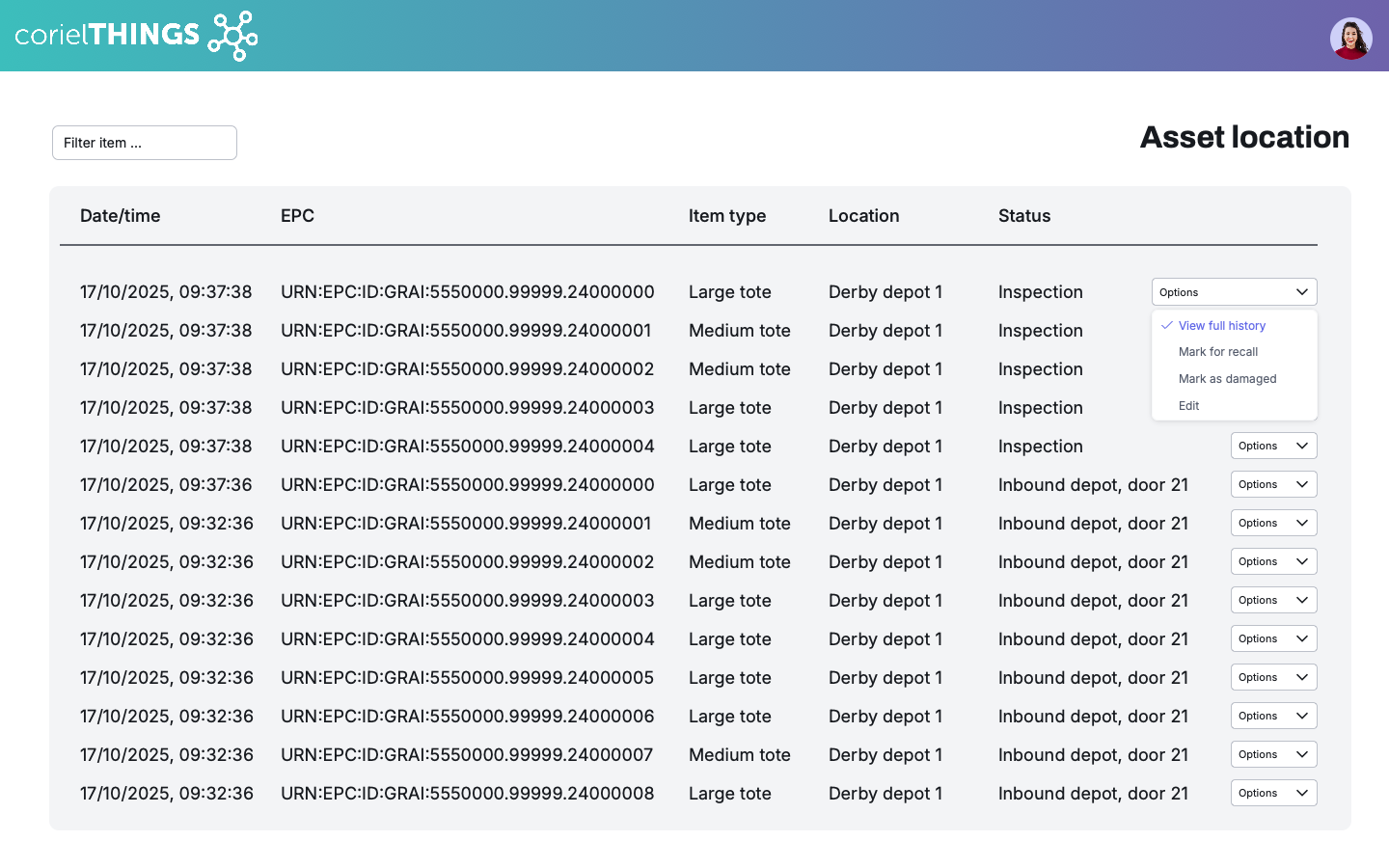

Know where your vehicles are at the points that matter …

Readers at key locations create authoritative events in real time. As soon as a vehicle passes a portal or gate, its identity and the location are recorded. Events are shared with maintenance, performance, and customer systems, providing a single version of the truth.

- Hands-free, operator-free identification at set points

- Immediate updates to planning and maintenance systems

- Last-seen location at depot, portal, wash or terminal

- APIs for sharing events with partners and terminals

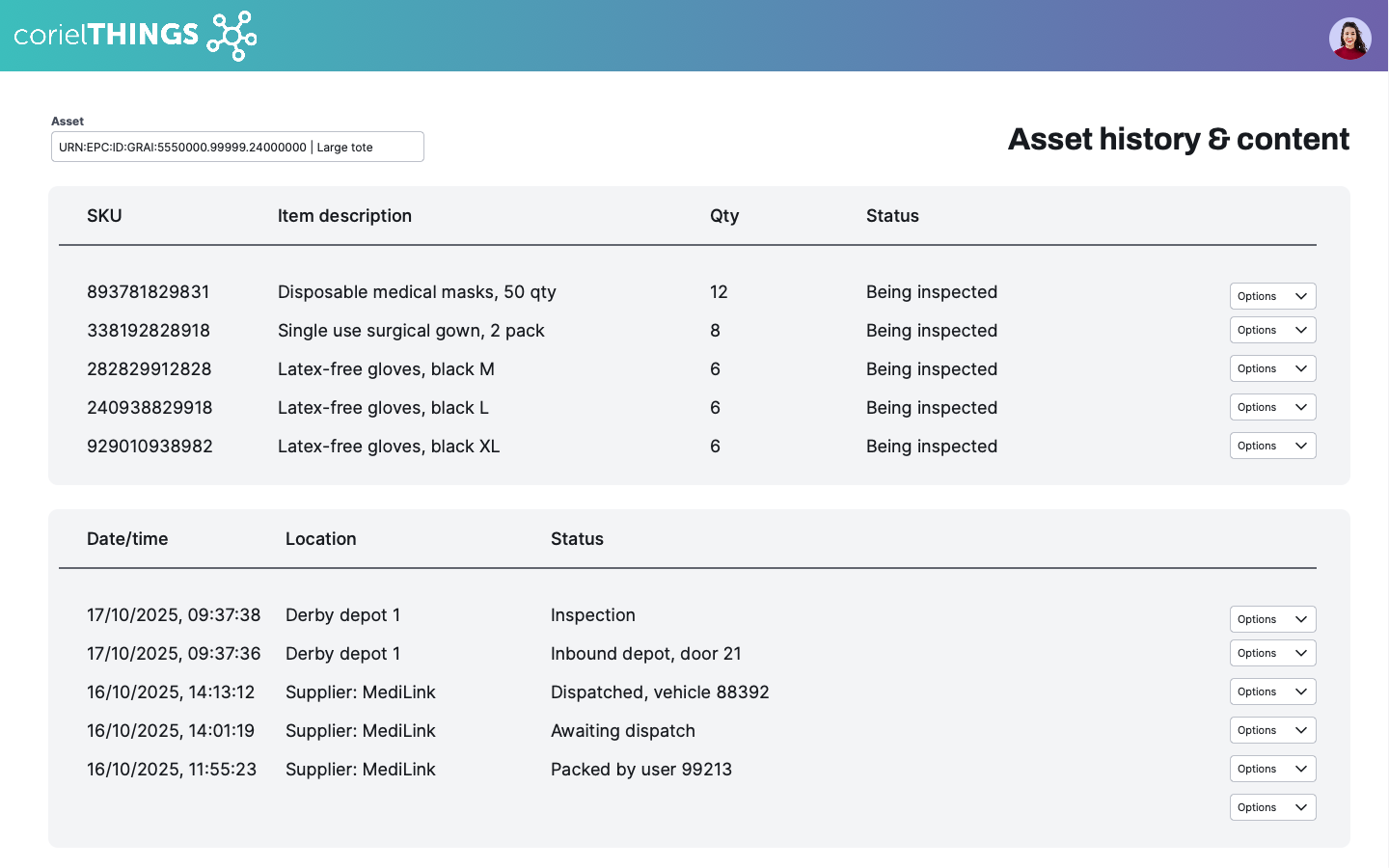

Evidence for maintenance and warranty …

Event histories confirm that required inspections or processes took place at the right time and mileage. Rules link reads to counters, tasks and warranty conditions so teams can prove compliance without manual reconciliation.

- Trigger tasks when units pass inspection or workshop areas

- Validate warranty windows and process steps automatically

- Combine events and outcomes into a single service record

- Create evidence packs for component and subsystem claims

What else can you do with corielTHINGS?

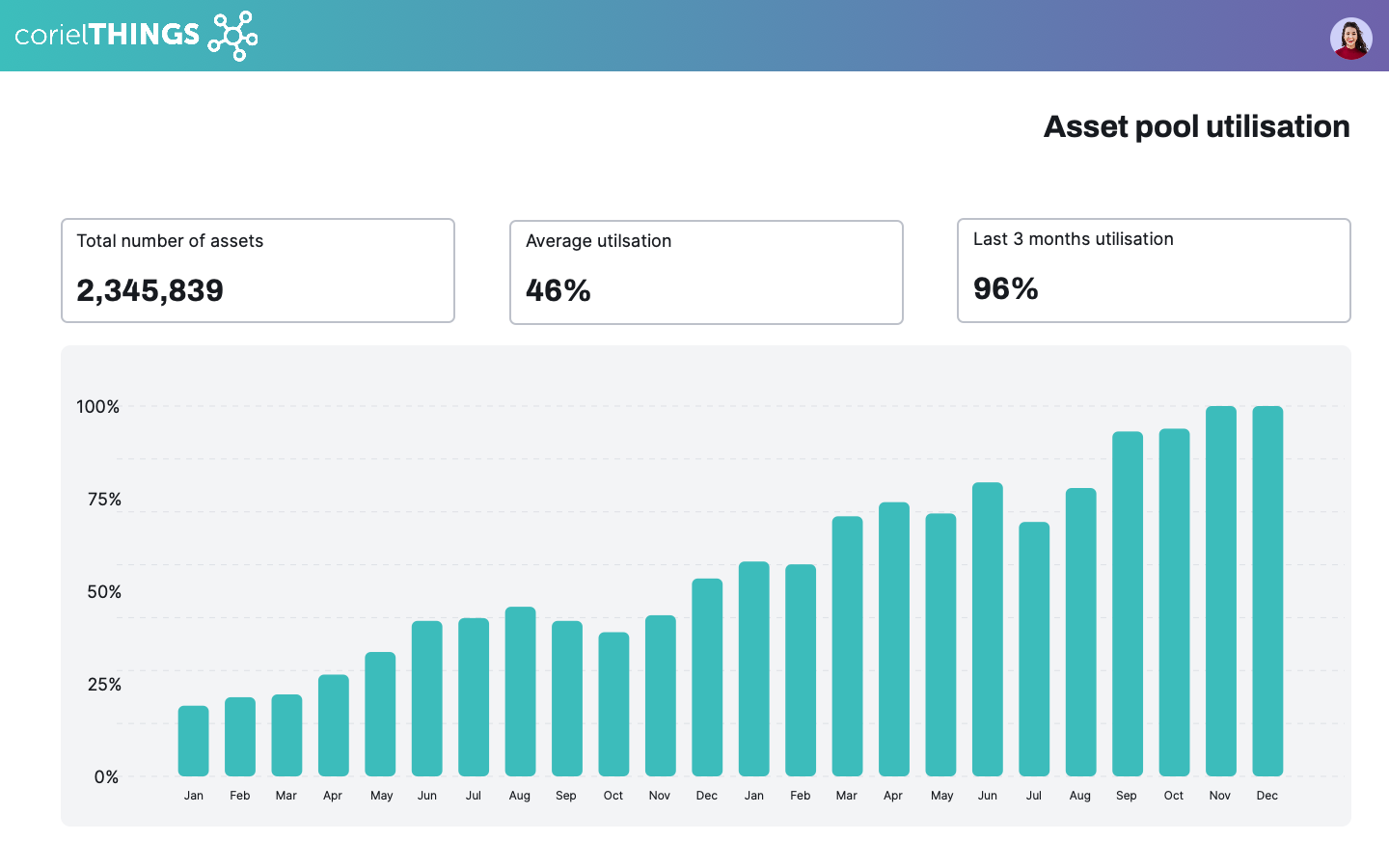

Visualise your supply chain

Simple reports and dashboards give you a ‘birds-eye’ view of what’s happening across your supply chain.

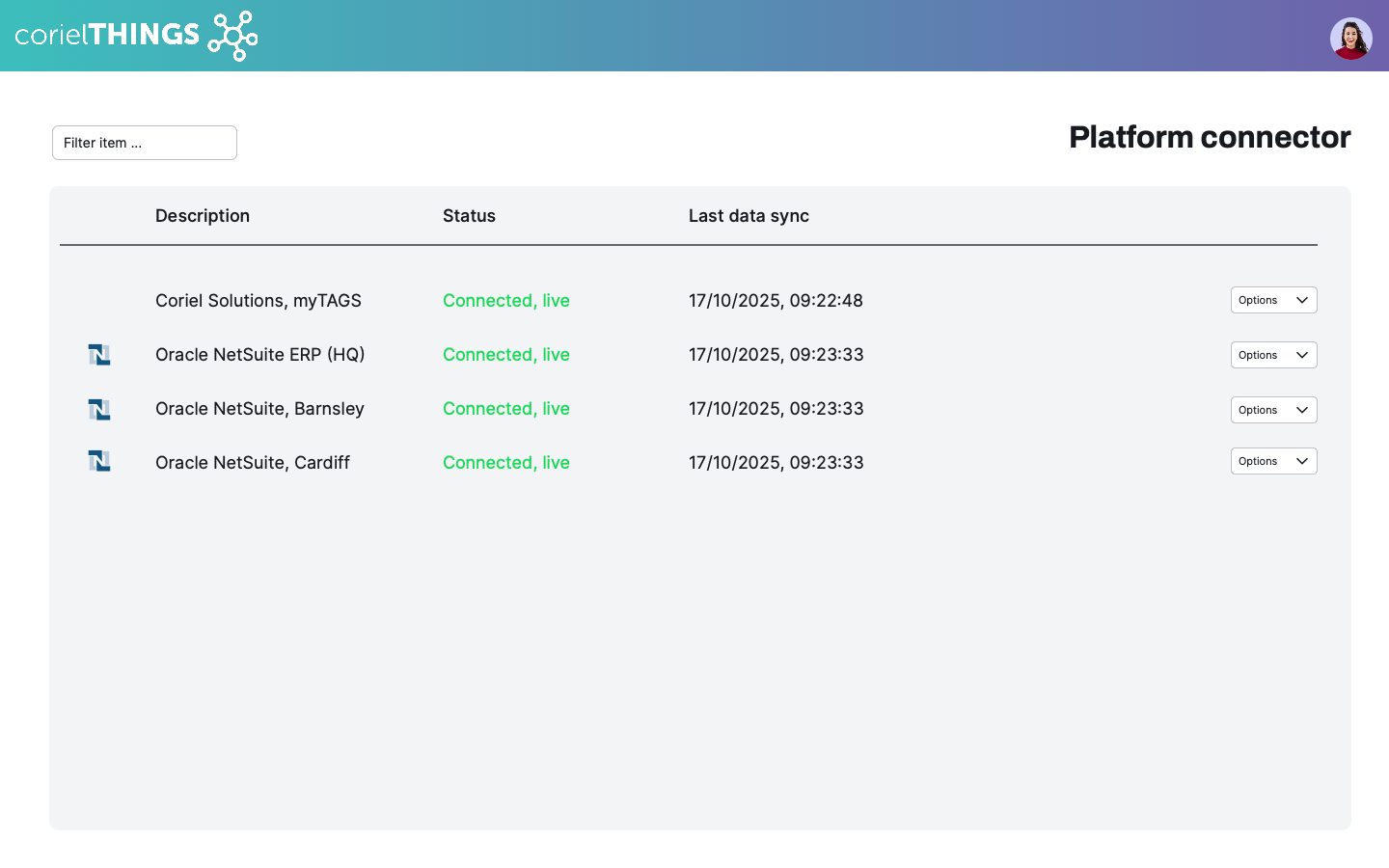

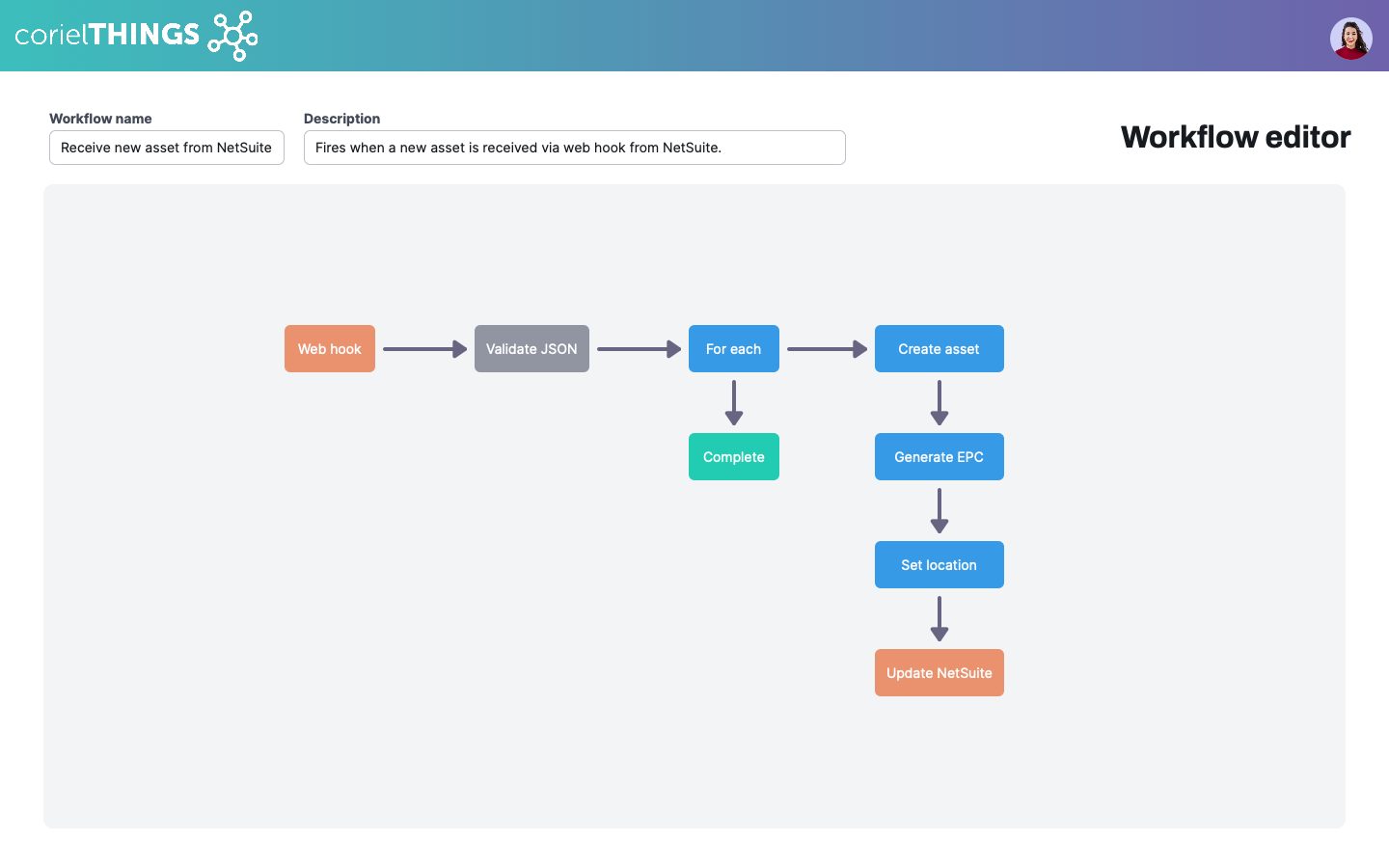

Live sync with your ERP

corielTHINGS is a completely connected platform, allowing you to integrate your ERP, WMS or bespoke systems via simple web calls.

Automatic Vehicle Identification news & content ...

How can RFID integration enhance manufacturing processes?

How can RFID integration enhance manufacturing processes? RFID already powers traceability in the world’s toughest supply chains. In manufacturing, integration turns tags and reads into actionable insight that cuts downtime, improves quality and unlocks true lean...

5 Steps to Successful RFID Label Application

RFID labels play a critical role in accurate asset tracking and inventory management. However, improper application can lead to peeling, poor readability, and even system failures. By following these five essential steps, you can ensure your RFID labels adhere...

Unlocking the future of supply chain logistics with AI and AutoID

Managing your data effectively across the supply chain has long been the holy grail for organisations of all shapes and sizes. With millions of barcodes and RFID tags being read by thousands of data collection devices, the scale of collected data has never been...

Useful links

Information about the Alstom TrainScanner system

Alstom TrainScanner project

More info on how Coriel Solutions helped enable the Alstom TrainScanner system